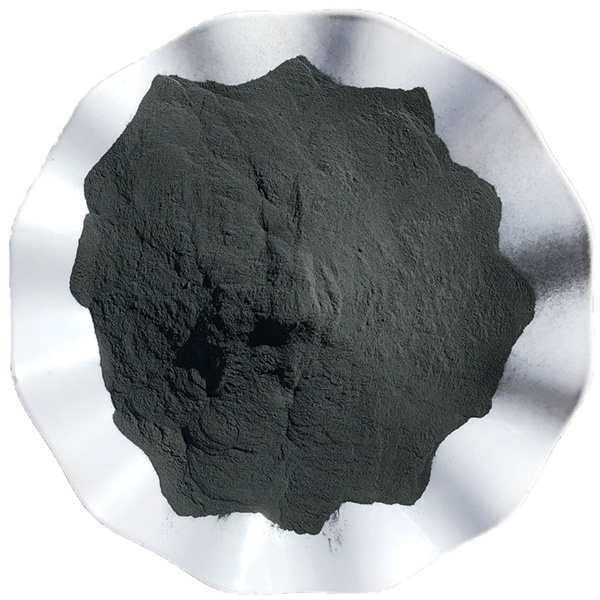

Titanium poeder is a versatile metal powder with unique properties that make it an important material for many applications. This article provides an overview of titanium powder, its properties, production methods, applications, and leading global suppliers.

Overview of Titanium Powder

Titanium powder is composed of fine titanium particles used to manufacture parts, coatings, and additives. Key properties include:

- Hoge sterkte-gewichtsverhouding

- Corrosieweerstand

- Biocompatibiliteit

- Hoog smeltpunt

- Lage dichtheid

- Strength retention at high temperatures

Titanium powder is available in various purity grades, particle sizes, and morphologies to suit different production processes and end-use requirements.

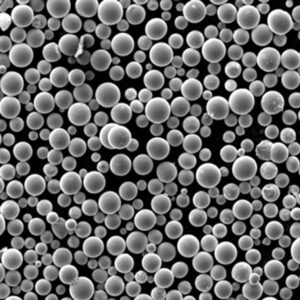

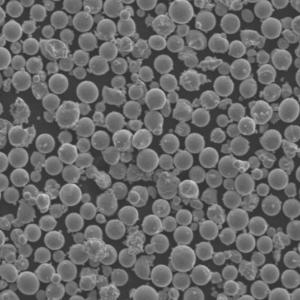

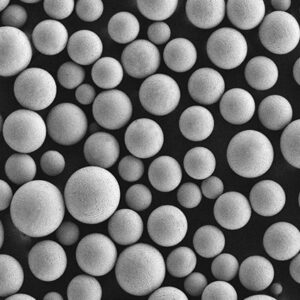

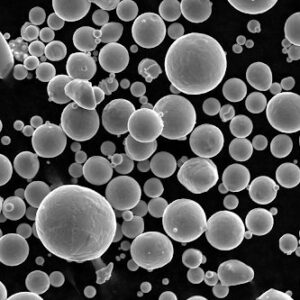

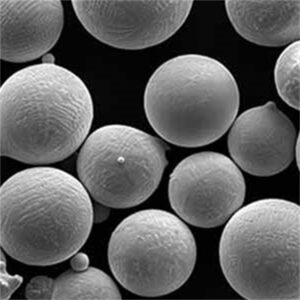

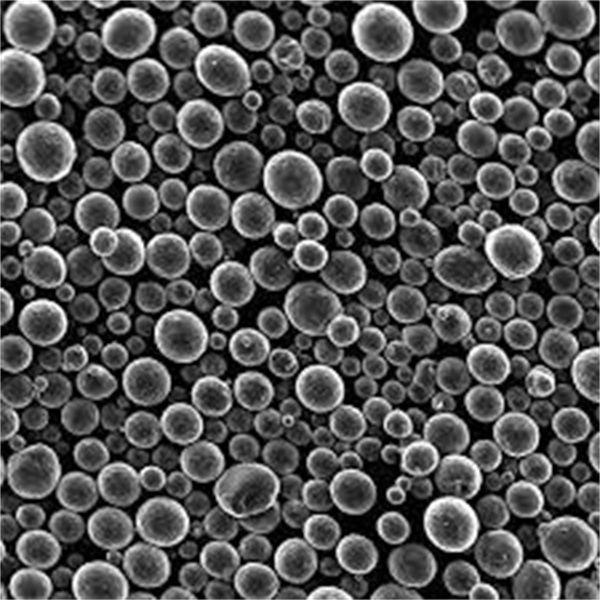

The most common production methods for titanium powder are gas atomization and plasma spheroidization. Suppliers offer both crude titanium powders as well as spheroidized, alloyed and plasma purified grades.

Titanium Powder Types

| Type | Beschrijving | Toepassingen |

|---|---|---|

| Puur titanium | 99.5-99.9% titanium content | Aerospace, medical, consumer products |

| Ti-6Al-4V | Titanium + 6% aluminum + 4% vanadium | Aerospace, automotive, implants |

| Ti64 | An alternative designation for Ti-6Al-4V | Aerospace, automotive, implants |

| Ti-6Al-7Nb | Titanium + 6% aluminum + 7% niobium | Lucht- en ruimtevaart, medisch |

| Other Titanium Alloys | Various compositions possible | Specialty applications |

Titanium Powder Characteristics

| Kenmerkend | Details | Betekenis |

|---|---|---|

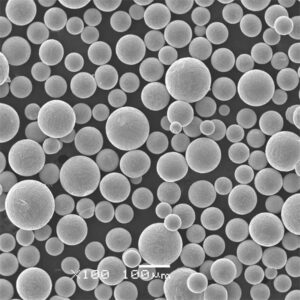

| Deeltjesgrootte | Range from 10-250 microns | Determines suitability for additive manufacturing or pressing applications |

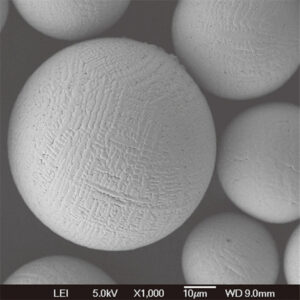

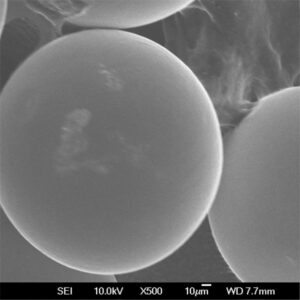

| Morfologie | May be irregular, angular, or spheroidal | Spheroidal powders have better flowability |

| Puurheid | Grades from CP1 to CP4 based on oxygen, nitrogen, carbon levels | Higher purity grades required for more demanding applications |

| Samenstelling legering | Varies based on aluminum, vanadium, other alloying content | Alloying elements enhance strength and modify properties |

| Productie methode | Gas atomized, plasma purified, hydride-dehydride | Affects particle characteristics like size distribution, shape, purity |

Titanium poeder specificaties

| Parameter | Bereik |

|---|---|

| Deeltjesgrootte | 10-150 microns typical |

| Zuurstofgehalte | <0.20% for Grade 1 titanium |

| Stikstofgehalte | <0.03% for Grade 1 titanium |

| Koolstofgehalte | <0.08% for Grade 1 titanium |

| Tik op dichtheid | 2.2-3.8 g/cc |

| Schijnbare dichtheid | >92% of absolute density |

Toepassingen van Titanium Poeder

The unique properties of titanium make its powder suitable for diverse applications across industries:

Lucht- en ruimtevaart

- Structural components

- Motoronderdelen

- Airframes

- Spacecraft

Medisch en tandheelkundig

- Joint replacements

- Tandheelkundige implantaten

- Chirurgische instrumenten

- Medische apparaten

Automobiel

- Valve systems

- Connecting rods

- Racing components

Chemische verwerking

- Corrosion resistant vessels

- Warmtewisselaars

- Pipework

Consumentenproducten

- Sportartikelen

- Horloges

- Eyeglasses

Additieve productie

- Lucht- en ruimtevaartcomponenten

- Auto-onderdelen

- Medische apparaten

- Consumentenproducten

Poeder-Metallurgie

- P/M titanium parts

- Master alloys

- Hard metals industry

Global Titanium Powder Suppliers

The complex production methods for titanium powder mean that manufacturing capacity is concentrated in the hands of a few large suppliers with proprietary technologies.

The leading global titanium powder suppliers include:

AP&C

Founded: 1997

Headquarters: Montreal, Canada

- Powders: Titanium, titanium alloys, nickel superalloys

- Grades: Ti-6Al-4V, Ti-6Al-7Nb, pure titanium

- Production capacity: 4,000 metric tons annually

- Markets served: Aerospace, medical, energy, automotive

ATI-poedermetalen

Founded: 1908

Headquarters: Pittsburgh, USA

- Powders: Titanium, nickel, specialty alloys

- Grades: Ti-6Al-4V Grade 5 and 23

- Production capacity: Over 5,000 metric tons annually

- Markets served: Aerospace, medical, automotive, oil & gas

CRS Holdings

Founded: 1987 Headquarters: Huntersville, USA

- Powders: Titanium, titanium alloys, nickel alloys

- Grades: Ti-6Al-4V, Ti-6Al-7Nb, commercially pure titanium

- Production capacity: 2,000 metric tons annually

- Markets served: Aerospace, defense, medical, automotive

GKN Hoeganaes

Founded: 1983

Headquarters: Cinnaminson, USA

- Powders: Titanium, steels, nickel alloys

- Grades: Ti-6Al-4V, plasma refined titanium

- Production capacity: Wide range of water and gas atomized powders

- Markets served: Additive manufacturing across industries

OSAKA Titaniumtechnologieën

Founded: 1946

Headquarters: Amagasaki, Japan

- Powders: Titanium alloys, nickel alloys, specialty metals

- Grades: Ti-6Al-4V, Ti-6Al-7Nb, high purity titanium

- Production capacity: Leading supplier in Japan

- Markets served: Aerospace, automotive, medical, electronics

Puris

Founded: 2019 as joint venture by Titanium Industries (1935) and Mitsui (1947)

Headquarters: Jerusalem, Israel

- Powders: Titanium alloys

- Grades: Ti-6Al-4V Grade 5

- Production capacity: Around 2,000 metric tons annually

- Markets served: Aerospace, medical, defense, automotive

Reading Alloys

Founded: 1988

Headquarters: Robesonia, USA

- Powders: Master alloys, titanium alloys

- Grades: Custom titanium master alloys

- Production capacity: Range of atomization equipment for different metals

- Markets served: Supplier to powder metal producers

SLM-oplossingen

Founded: 1996

Headquarters: Lubeck, Germany

- Powders: Titanium alloys, aluminum alloys, nickel alloys, tool steel

- Grades: Ti-6Al-4V Grade 5 and 23, aluminum alloys

- Production capacity: Key supplier for additive manufacturing industry

- Markets served: Aerospace, medical, automotive sectors

Titanium Powder Pricing

| Leverancier | Cijfer | Deeltjesgrootte | Prijzen |

|---|---|---|---|

| AP&C | Ti-6Al-4V | 45-100 micron | $55/kg |

| ATI-poedermetalen | Ti-6Al-4V ELI | 63-106 microns | $50/kg |

| CRS Holdings | Ti-6Al-4V | 75-150 micron | $45-50/kg |

| GKN Hoeganaes | Ti-6Al-4V plasma | 15-45 micron | $120+/kg |

| Osaka Titanium | Pure titanium | 45 microns | $100/kg |

Titanium powder is more expensive compared to steel powder costs due to complex manufacturing and economies of scale. However, buyers focus on quality, purity and product performance instead for critical applications.

Titanium vs Alternative Powders

Titanium vs. Steel

Titanium has 40% lower density than steel and retains strength better at elevated temperatures. It has excellent corrosion resistance due to surface oxide layer. More expensive than stainless steel powder.

Titanium vs. Aluminum

Almost twice as strong as aluminum powder but with only 60% higher density. Maintains properties at higher temperatures. Much better corrosion resistance than aluminum due to oxide layer.

Titanium vs. Nickel Superalloys

Titanium has lower density providing higher specific strength. Nickel alloys can operate at extreme temperatures exceeding titanium’s useful limits. Titanium cheaper alternative to expensive superalloys.

Titanium vs. Cobalt Chrome

Half the density of cobalt chrome alloys. Excellent biocompatibility unlike concerns with cobalt and chromium release in body. Significantly cheaper material option.

Choosing a Titanium Poeder Leverancier

Key factors in choosing a titanium powder supplier:

Technische capaciteit

- Ability to manufacture grades needed

- Quality control over entire production process

- Consistentie in chemische samenstelling

Track Record

- Years of experience in industry

- Reputatie voor productkwaliteit en service

Kwaliteitscertificeringen

- AS9100, ISO 9001

- Specific aerospace, defense or nuclear certifications

Maatwerk

- Ability to customize alloy composition and particle characteristics

Prijzen

- Quantity discounts may be available

- Large buyers can negotiate pricing

- Pay premiums for high purity grade powder

Doorlooptijden

- Typical 6-8 weeks for ordered powders

- Rush orders possible for additional fee

Plaats

- Shipping costs a significant part of powder price

- Onsite visits useful to audit supplier

FAQ

Q: What is the difference between commercially pure titanium vs titanium alloy powder?

A: Commercially pure titanium powder has 99.5-99.9% titanium content with low oxygen, nitrogen and carbon. Titanium alloy powders like Ti-6Al-4V contain aluminum, vanadium, or other elements to enhance properties like strength.

Q: What particle size titanium powder is optimal?

A: For pressing and sintering 75-150 microns is common. For additive manufacturing processes, finer 15-45 micron powder is preferred to achieve good resolution.

Q: Does titanium powder require special handling precautions?

A: Yes, titanium fines are flammable and create explosion hazard. Inert gas blanketing and proper grounding is used. Water contact causes hydrogen absorption issues.

Q: How to determine which titanium grade is best for my application?

A: Consult closely with potential suppliers on technical requirements. Ti-6Al-4V is the most common grade but others like Ti-6Al-7Nb suit specific needs. Get test samples to evaluate performance.

Q: What methods can produce titanium powder suitable for 3D printing?

A: Gas atomization and plasma spheroidization create fine spherical titanium powders optimal for additive manufacturing. Hydride-dehydride and mechanical milling methods also produce printable powder.

Q: What post-processing is required on additively manufactured titanium parts?

A: Hot isostatic pressing (HIP) helps eliminate porosity in printed parts. Additional heat treatments, surface finishing, and machining may be needed depending on final properties and tolerances required.