With exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility, titanium is a highly valued material for additive manufacturing across aerospace, medical, automotive and industrial applications. This overview explores the different titanium am powders, their corresponding properties, post-processing treatments, leading global suppliers, and example use cases by industry.

Overzicht van titanium am poeders

Key properties make titanium such an ideal material for powder bed fusion and directed energy deposition AM processes:

- High strength – often exceeding annealed titanium while rivaling Ti-6Al-4V

- Low density – high strength-to-weight ratio, reduced printed part weight

- Corrosion resistance – protective surface oxide shield

- Biocompatibility – suited for medical devices and implants

- Ability to alloy – tailor properties like strength and hardness

- Cost-effectiveness – lower material waste versus machining from blocks

- Buy-to-fly ratios exceeding 90%+ – optimized designs save weight and material

Paired with the design freedom AM facilitates, titanium unlocks new potential applications.

Titanium Alloy Powder Options for AM

Popular titanium alloys leveraged today include commercially pure grades, alpha and alpha-beta alloys and novel proprietary grades like Titanium 6242.

Common Titanium Alloy Compositions

| Legering | Al% | V% | Fe% | O% | Ander |

|---|---|---|---|---|---|

| CP Ti Grade 1 | – | – | ≤ 0.20 | ≤ 0.18 | – |

| CP Ti Grade 2 | – | – | ≤ 0.30 | ≤ 0.25 | – |

| Ti-6Al-4V | 5.5-6.5 | 3.5-4.5 | ≤ 0.25 | ≤ 0.13 | – |

| Ti 6242 | 5.8-6.8 | – | ≤ 0.30 | ≤ 0.20 | Mo, Zr |

Trace oxygen, nitrogen and carbon are strictly limited to ensure optimal AM processing and mechanical properties.

Specifications for titanium am poeders

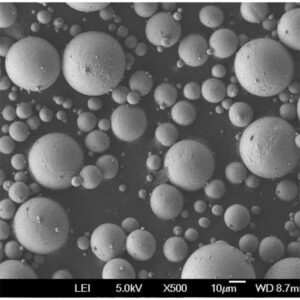

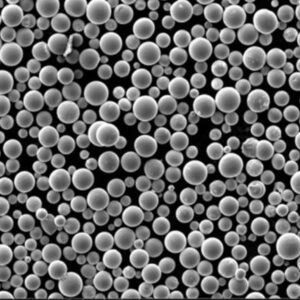

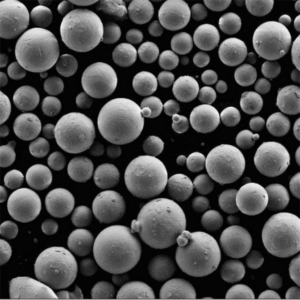

High purity, spherical titanium powder with controlled particle size distribution is required for defect-free, dense AM components.

Titanium Powder Particle Size Distribution

| Meting | Specificatie |

|---|---|

| Maatbereik | 15 - 45 μm |

| Mean Particle Size | 25-35 μm |

| Deeltjesvorm | Overwegend bolvormig |

Sphericity promotes powder spreadability. Controlled distribution prevents segregation issues during application and recyclability.

Post-Processing Procedures for AM Titanium Parts

Common post-treatment options for additively manufactured titanium components include:

Methoden voor nabewerking

Stressverlagend

Low temperature aging eliminates residual stresses from the build process, preventing potential warpage and cracking.

Oppervlakteafwerking

Enhances surface finish for precision dimensions, break sharp edges or improve aesthetic appearance.

Heet isostatisch persen

Densifies any internal porosity by simultaneous elevated temperature and isostatic pressure application. Required for dynamic end-use applications.

Hittebehandeling

Alters microstructure of Ti-6Al-4V and other titanium alloys to enhance mechanical properties like ductility and fatigue life.

Bewerking

Brings high precision dimensions and surface finishes for bearing and sealing surfaces on AM near-net shape parts.

Additive Manufacturing Techniques for Titanium Powder

Modern metal 3D printing uses micro welding of fine titanium to construct complex components. Two common approaches include:

Comparison of Titanium AM Process Options

| Methode | Beschrijving | Voordelen | Beperkingen |

|---|---|---|---|

| Poederbedfusie | Laser or e-beam fuses regions of powder bed selectively according to digital model | Exceptional geometric capabilities and material versatility suitable for end-use functional titanium components | Slower build speeds than DED; size limitations from machine bed |

| Gerichte energiedepositie | Focused heat source melts metal powder spray nozzle | Larger components possible; Cumulative build area. Ideal for repairs and coatings. | Poorer surface finish; Higher porosity – requires extensive post-processing |

Laser based approaches currently see the widest adoption for printing high purity titanium alloys thanks to precision and material performance.

Toepassingen van titanium am poeders

Thanks to titanium material advantages like high mechanical performance per unit weight combined with AM design freedoms, applications include:

Industries Adopting Titanium AM Parts

Lucht- en ruimtevaart – engine brackets, drone parts, satellite components

Medisch & tandheelkundig – implants, prosthetics, surgical instruments

Automobiel – motor sports gear, custom brackets

Olie gas – deep sea tooling, valves and pumps

Stroomopwekking – lightweight impellors, turbine blades

Novel engineered alloys like Ti-6242 push capabilities even further allowing titanium across high growth sectors.

Leading Suppliers of Titanium Print Powders

Key producers of spherical titanium powders for reliable AM processes include:

Titanium poeder fabrikanten

| Bedrijf | Algemene cijfers | Pricing/Kg |

|---|---|---|

| AP&C | Ti-6Al-4V, Ti-6242, Grade 2, 23 | $50 – $350 |

| The Linde Group | Ti-6Al-4V, Grade 2, 23, 5 | $200 – $600 |

| Wolfram Metal Powder | Ti-6Al-4V, Grade 5 | $100 – $500 |

| Sandvik | Ti-6Al-4V | $120 – $310 |

Prices depend significantly on purity standards, powder size parameters, certified chemistry, and purchase volumes.

FAQ

What titanium alloy grade is best for medical or dental AM parts?

Medical grade 5 titanium with strict chemistry controls is recommended for bio-inert implant applications requiring optimal biocompatibility and high fatigue performance.

Why is low oxygen content critical for titanium print powders?

High oxygen leads to excess titanium oxides reducing fusion capabilities, ductility, fatigue life and mechanical performance. Oxygen is limited to remain under 0.18-0.2% levels.

What titanium alloys benefit the most from post-processing treatments?

Prominent dual heat treatments for Ti-6Al-4V enhance tensile strength while improving ductility. Grade 2 titanium achieves the highest tensile gains from annealing relieving followed by aging response.

Is surface finishing required for Titanium AM parts?

Certain applications require dimensional accuracy, tribological, aesthetic or inactivation needs best addressed by surface enhancement – including precision CNC machining, grinding/polishing, EDM, shot peening, anodization, plasma electrolytic oxidation etc.

How should suppliers be evaluated for printing titanium powder orders?

Leading critical characteristics used by additive manufacturers and designers for qualifying titanium powder suppliers beyond reasonable pricing include: spherical morphology, tight control of particle size distribution, extremely low gaseous impurity contents (especially oxygen and nitrogen), lot traceability through stringent quality management system, responsive technical expertise, sampling availability and certifications proving standardized in-house testing protocols.