Specialty metal powders refer to metals that have been processed into fine particulate form for use in advanced manufacturing techniques. They exhibit unique properties that make them suitable for specialized applications across industries like aerospace, medical, electronics, and more.

This article will provide a comprehensive overview of various types of specialty metal powders, their composition and characteristics, applications, specifications and grades, suppliers, pricing, and advantages vs limitations.

Types of Specialty Metal Powders

There are many categories and varieties of specialty metal powders used in different technologies. Some major types include:

| Type | Beschrijving |

|---|---|

| Nikkellegeringen | Inconel, Monel, Hastelloy, Nilo alloys with nickel plus chromium, iron, molybdenum etc. High strength and corrosion resistance at high temperatures |

| Kobaltlegeringen | Haynes alloys with cobalt and chromium/tungsten/molybdenum. Biocompatibility for implants |

| Titanium legeringen | Ti-6Al-4V, Ti-6Al-7Nb etc. Lightweight, strength, biocompatibility |

| Vuurvaste metalen | Tungsten, molybdenum, tantalum. Extremely high melting points |

| Magnetic Alloys | Iron, nickel or cobalt alloys with high permeability and low coercivity |

| Thermal Spray Powders | Spheroidal powders for coatings to resist wear, corrosion etc. |

Advantages of Powder Metallurgy

Compared to conventional metal processing, powder metallurgy offers benefits like:

- Tighter tolerances

- Ability to produce complex or porous parts

- High repeatability

- Low material waste

- Cost effectiveness for small productions

This makes powder metals suitable for special purposes where traditional methods may have limitations.

Samenstelling en kenmerken

Specialty metal powders can contain a variety of alloying elements to achieve desired properties. Some typical compositions and characteristics are outlined below:

| Materiaal | Typische compositie | Kenmerken |

|---|---|---|

| Nikkellegeringen | Ni, Cr, Fe, Nb, Mo | Resistant to heat, corrosion. Good strength and toughness |

| Kobaltlegeringen | Co, Cr, W, Ni, Mo | Biocompatible, high hardness and wear resistance |

| Titanium legeringen | Ti, Al, V, Nb, Ta | Extremely strong yet lightweight. Bio-inertness |

| Vuurvaste metalen | W, Mo, Ta | Outstanding high temperature properties, thermal/electrical conductivity |

| Magnetic Alloys | Fe, Ni, Co, Nd, Sm | High saturation magnetization and magnetic permeability |

The specific percentages of each element can be varied to produce powders with slightly different properties for intended applications. More exotic specialty alloys are also possible through blending multiple metals.

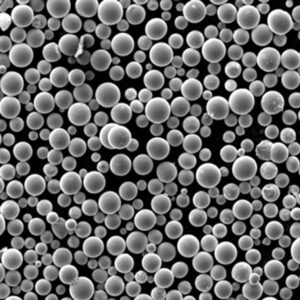

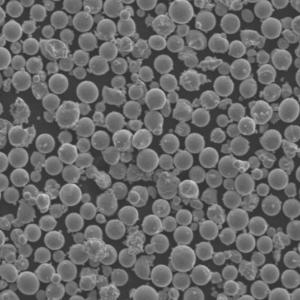

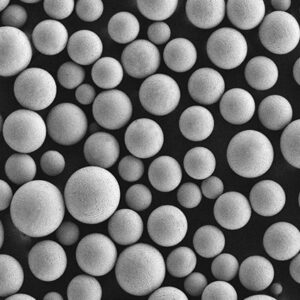

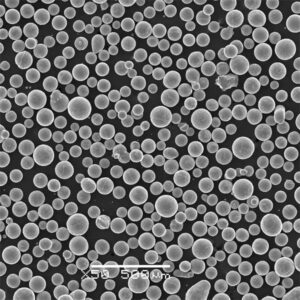

Particle Characteristics

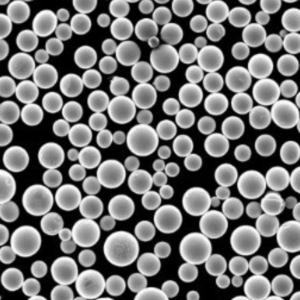

In addition to composition, powder characteristics like particle shape, size distribution, flowability, and purity also impact performance.

- Deeltjesvorm – Spherical, irregular, mixed. Determines packing density and sintering behavior.

- Grootteverdeling – Range and distribution of sizes. Affects densification and properties.

- Vloeibaarheid – Crucial for dispensing precision in AM. Improved by sphericity and size uniformity.

- Puurheid – Oxygen/nitrogen content affects quality. Higher is better.

Manufacturers closely control these powder attributes to guarantee consistency between batches.

Applications of Specialty Metal Powders

The unique benefits of specialty metal powders make them suitable for niche applications where traditional metal products fall short. Some examples include:

| Industrie | Toepassingen |

|---|---|

| Lucht- en ruimtevaart | Turbine blades, aircraft fittings, rocket nozzles |

| Medisch | Orthopedic/dental implants, surgical instruments |

| Automobiel | Lightweight chassis parts, high performance components |

| Elektronica | Shielding, contacts, leadframes, connectors |

| Industrieel | Tooling, heat treatment fixtures, wear/corrosion resistant coatings |

Other common applications are chemical processing equipment, sporting goods, watchmaking components etc. Usage continues to grow with wider adoption of additive manufacturing.

Rangen en specificaties

Like conventional metals, powder metallurgy grades are standardized by professional organizations to enable consistent quality and performance. Some key standards include:

| Standaard | Organisatie | Materialen |

|---|---|---|

| ASTM | ASTM International | Nickel, cobalt, titanium alloys |

| UNS | SAE Internationaal | Specialty metal alloys |

| ISO | International Organization for Standardization | Wide range metals and ceramics |

Within each standard, materials are designated unique codes for identification. Additionally, specifications related to composition limits, powder characteristics, sampling, testing etc. are provided to regulate quality.

Chemistry conformation certificates and test reports are supplied by reputable manufacturers to validate compliance with the purchased specification. Custom grades outside standards are also possible for proprietary applications.

Leveranciers en prijzen

There are a number of leading global suppliers providing specialty metal powders for commercial use:

| Leverancier | Typical Materials | Average Pricing |

|---|---|---|

| Sandvik | Nickel, cobalt, titanium alloys | $50 – $100 per kg |

| Praxair | Nickel, iron, tungsten alloys | $75 – $250 per kg |

| Hoganas | Gereedschapsstaal, roestvrij staal | $30 – $150 per kg |

| GKN | Titanium, aluminiumlegeringen | $100 – $300 per kg |

| Carpenter Tech | Extensive specialty alloys | $250 – $500 per kg |

Pricing ranges significantly depending on alloy complexity, order volume, powder characteristics and quality standards. Generally spherical powders with controlled size distribution command premium pricing.

Comparison Between Materials

There is no universally best specialty alloy – specific tradeoffs exist between various powder metal options:

| Parameter | Nikkellegeringen | Titanium legeringen | Vuurvaste metalen |

|---|---|---|---|

| Kracht | Erg goed | Uitstekend | Goed |

| Hardheid | Goed | Erg goed | Uitstekend |

| Taaiheid | Uitstekend | Goed | Gemiddeld |

| Corrosieweerstand | Uitstekend | Erg goed | Gemiddeld |

| High Temperature Resistance | Uitstekend | Gemiddeld | Uitstekend |

| Biocompatibiliteit | Gemiddeld | Uitstekend | Gemiddeld |

| Kosten | Hoog | Heel hoog | Gemiddeld |

Belangrijkste leerpunten:

- Nickel alloys offer best all-round properties but are expensive

- Titanium alloys have outstanding strength-to-weight ratio but can lack ductility

- Refractory metals withstand extreme temperatures but are less corrosion resistant

- Correct selection depends on critical performance needs for the application

Advantages of Powder Metallurgy

Some notable benefits of speciale metaalpoeders:

Higher purity – Rapid solidification in atomization allows higher achievable purity over conventional cast/wrought metals. This expands viable applications and operating envelopes.

Precision attributes – Consistent powder characteristics enable repeatable output, tighter tolerances and quality control for critical components like aerospace turbines and medical implants.

Complexe geometrieën – Specialty powders empower production of topologically optimized, lightweight or porous components impossible through subtractive techniques.

Customizability – Alloy chemistry and powder attributes can be tailored to meet specific mechanical, physical or biological property needs.

Duurzaamheid – Additive techniques have lower buy-to-fly ratio and use less material over machining from bulk stock. This supports greener manufacturing.

Challenges With Powder Metallurgy

Despite major advances, some inherent limitations still remain:

Kwaliteitscontrole – Ensuring reliable material performance through consistent feedstock and rigorously controlled processing parameters. Much progress has been made in recent years regarding this.

Herhaalbaarheid – There exist batch-to-batch variations in powder production and slight differences between AM builds. These can affect measurement of mechanical properties. Continued research aims to strengthen confidence.

Kosten – Specialty alloy powders are priced higher than standard grades. However automated AM can offset this through efficiency at production scale.

Performance data – Broad data on powder material behavior only recently emerging with increased adoption. Published values may have statistical distribution versus single fixed numbers.

Regulatory approval – Industries like aerospace and medical have traditionally lengthy qualification processes that powder metal components must still satisfy before full-scale deployment, despite large underlying demand.

In summary, metal powders present vast opportunities but still undergo standardization and maturation as a developing technology sector serving established industries.

FAQ

This FAQ section provides answers to common inquiries on powder metallurgy for reference:

What are the most widely used specialty metal powders today?

Titanium alloys, nickel-based superalloys, cobalt-chrome alloys and tool steels comprise majority of demand. Main applications are in aerospace engines, joint replacement implants, automotive/industrial tooling and tool steels for molds and dies.

What methods can be used to produce specialty metal powder?

Common commercial production techniques include gas atomization, plasma atomization, electrolysis and carbonyl decomposition. Each have relative advantages – gas atomization offers the best combination of cost and consistent powder size/shape.

How are metal powders characterized?

Typical characteristics examined are particle size distribution, morphology, flow rate, tap density, chemical composition, microstructure and contamination levels. These influence suitability for AM processes and final part properties.

What size range do specialty powders for AM fall under?

Vast majority of powders fall between 10 microns to 100 microns. Finer particles can combust or be hazardous to handle while larger particles negatively affect resolution, density and surface finish.

What is an inert gas atomized specialty alloy?

It refers to a high performance powder produced by atomizing the molten metal stream using an inert gas like argon or nitrogen to avoid contamination. This is the preferred production method for reactive alloys.

How are parts post-processed after AM?

Common post-processing includes HIP (hot isostatic pressing), heat treatment, Hot Isostatic Pressing (HIP), surface finishing, coating, and final inspection/testing to meet application requirements.