Zuiver aluminiumpoeder

Zuiver aluminiumpoeder bevat 99% of een hoger aluminiumgehalte. Het biedt een lage dichtheid gecombineerd met goede ductiliteit, geleidbaarheid en corrosieweerstand.

Lage MOQ

Zorg voor een lage minimale bestelhoeveelheid om aan verschillende behoeften te voldoen.

OEM & ODM

Bied op maat gemaakte producten en ontwerpdiensten om aan de unieke behoeften van de klant te voldoen.

Voldoende voorraad

Zorg voor een snelle orderverwerking en bied een betrouwbare en efficiënte service.

Klanttevredenheid

Producten van hoge kwaliteit leveren waarbij klanttevredenheid centraal staat.

deel dit product

Inhoudsopgave

Overview of Pure Aluminum Powder

Zuiver aluminiumpoeder bevat 99% of een hoger aluminiumgehalte. Het biedt een lage dichtheid gecombineerd met goede ductiliteit, geleidbaarheid en corrosieweerstand.

Key properties and advantages of pure aluminum powder include:

Pure Aluminum Powder Properties and Characteristics

| Eigenschappen | Details |

|---|---|

| Samenstelling | 99% or higher Al content |

| Dikte | 2,7 g/cc |

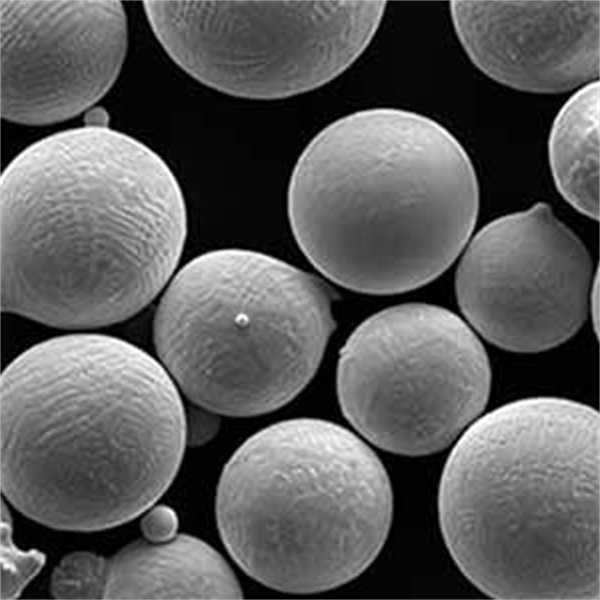

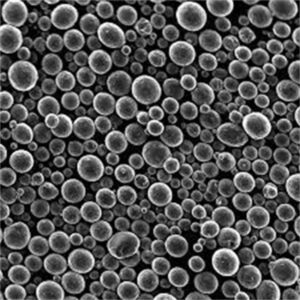

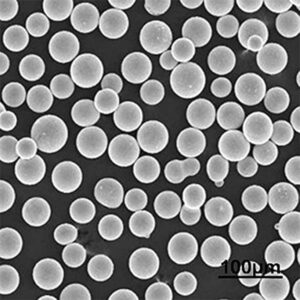

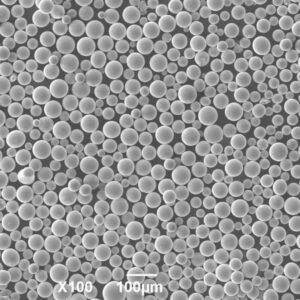

| Deeltjesvorm | Bolvormig, onregelmatig |

| Maatbereik | 1-150 micron |

| Schijnbare dichtheid | Tot 50% ware dichtheid |

| Geleidbaarheid | Excellent electrical and thermal conductivity |

| Corrosieweerstand | Good due to protective oxide layer |

Pure aluminum powder is suitable for applications like thermite welding, diamond tools, conductive coatings, pyrotechnics, and metal injection molding.

Pure Aluminum Powder Composition

Typical composition of pure aluminum powder:

Pure Aluminum Powder Composition

| Element | Gewicht % |

|---|---|

| Aluminium (Al) | 99% min |

| Silicium (Si) | Maximaal 0,5% |

| Ijzer (Fe) | Maximaal 0,5% |

| Koper (Cu) | Maximaal 0,05% |

| Mangaan (Mn) | Maximaal 0,05% |

| Magnesium (Mg) | Maximaal 0,05% |

| Other impurities | Maximaal 0,05% |

- Aluminum provides low density, ductility and conductivity

- Impurity levels of other elements are carefully controlled

- High aluminum purity provides optimal electrical and thermal conductivity

The high aluminum content ensures excellent conductivity combined with good corrosion resistance and moderate strength.

Pure Aluminum Powder Physical Properties

Pure Aluminum Powder Physical Properties

| Eigendom | Waarden |

|---|---|

| Dikte | 2,7 g/cc |

| Smeltpunt | 660°C |

| Warmtegeleiding | 237 W/mK |

| Elektrische weerstand | 2.65 μΩ-cm |

| CTE | 23.1 x 10^-6 /K |

| Reflectivity | 87% at 400 nm wavelength |

- Very low density compared to most metals

- High reflectivity and thermal conductivity

- Low electrical resistivity provides high conductivity

- Relatief hoge CTE vereist ontwerpoverwegingen

- Maintains strength up to moderately high temperatures

The properties make pure aluminum suitable for lightweight applications needing electrical/thermal conductivity.

Pure Aluminum Powder Mechanical Properties

Pure Aluminum Powder Mechanical Properties

| Eigendom | Waarden |

|---|---|

| Treksterkte | 90-100 MPa |

| Opbrengststerkte | 35-45 MPa |

| Verlenging | 35-40% |

| Hardheid | 25-35 HB |

| Vermoeidheid sterkte | 50-90 MPa |

| Afschuifsterkte | 60-65 MPa |

- Relatively low tensile and yield strength

- Very high elongation provides excellent ductility

- Low hardness compared to most metals

- High fatigue strength suited for cyclic loading

- Properties can be enhanced through alloying additions

The properties make pure aluminum suitable for soft, ductile applications requiring conductivity and formability.

Pure Aluminum Powder Applications

Typical applications of pure aluminum powder include:

Pure Aluminum Powder Applications

| Industrie | Toepassingen |

|---|---|

| Thermite welding | Rail welding, metal joining |

| Additieve productie | Low strength components |

| Explosives and pyrotechnics | Thermite compositions |

| Powder coatings | Conductive and resistant coatings |

| Diamond tools | Metal matrix with diamond particles |

| Vuurwerk | Fuel and pyrotechnic compositions |

Enkele specifieke producttoepassingen:

- Thermite mixtures for in-situ metal joining and welding

- Low melting point casting alloys

- Electrically conductive coatings and RF shielding

- Aluminum-diamond tools for stone cutting

- Flash powder and pyrotechnic compositions

- Metal injection molding of non-structural parts

The ductility, conductivity and reactivity make pure aluminum suitable for these niche applications.

Pure Aluminum Powder Specifications

Key specifications for pure aluminum powder include:

Pure Aluminum Powder Specifications

| Standaard | Beschrijving |

|---|---|

| ASTM B787 | Standard for pure aluminum powders |

| ASTM B859 | Specs for aluminum and aluminum alloy powders |

| DIN 1718-1 | Designation system for aluminum and aluminum alloys |

| GJB320B | Chinese military standard for aluminum and aluminum alloy powders |

Deze definiëren:

- Minimum 99% aluminum content

- Limits on impurities like Fe, Si

- Powder characteristics like apparent density and particle size distribution

- Approved production methods like atomization

- Sampling and testing protocols

Meeting the standards ensures suitability for applications needing high purity aluminum powder.

Pure Aluminum Powder Particle Sizes

Pure Aluminum Powder Particle Size Distribution

| Maat | Kenmerken |

|---|---|

| 1-10 micron | Ultrafine grade used in printing pastes |

| 10-45 micron | Fine grade suitable for coatings, pressing |

| 45-150 micron | Coarse grade offers better flowability |

- Finer sizes provide a smooth finish and high reactivity

- Coarser powder has improved flow for automated processing

- Both spherical and irregular particle shapes are available

- Size distribution depends on targeted use

Controlling particle size distribution optimizes processing behavior, density, reactivity, and finish.

Pure Aluminum Powder Apparent Density

Pure Aluminum Powder Apparent Density

| Schijnbare dichtheid | Details |

|---|---|

| Tot 50% ware dichtheid | For irregular morphology powder |

| 1.3-1.7 g/cc | Higher for spherical powder |

- Spherical powder shape provides higher apparent density

- Irregular particles have lower density around 30-40%

- Higher density improves powder flow and compactibility

- Waarden tot 60% zijn mogelijk met geoptimaliseerd bolvormig poeder

Een hogere schijnbare dichtheid leidt tot een betere productieproductiviteit en onderdeelkwaliteit.

Pure Aluminum Powder Production

Pure Aluminum Powder Production

| Methode | Details |

|---|---|

| Verneveling | Molten aluminum stream broken into fine droplets that solidify into powder |

| Kogel malen | Mechanical milling classifies coarse powder into fine powder |

| Gloeien | Removes internal stresses and improves powder compressibility |

| Zeven | Classificeert poeder in fracties van verschillende grootte |

- Atomization allows large volume production with controlled particle sizes

- Milling provides lower cost size reduction of coarse powder

- Annealing and sieving provide customized powder sizes and shapes

Combination of methods produces high purity aluminum powder with application-specific characteristics.

Pure Aluminum Powder Pricing

Pure Aluminum Powder Pricing

| Factor | Impact op de prijs |

|---|---|

| Puurheid | Hogere zuiverheidsgraden kosten meer |

| Deeltjesgrootte | Ultrafijn poeder is duurder |

| Bestelvolume | Bulk orders get discounted pricing |

| Productie methode | Complexe methoden verhogen de kosten |

| Verpakking | Special packaging adds cost |

Indicatieve prijzen

- Fine pure aluminum powder: $3-6 per kg

- Coarse pure aluminum powder: $2-4 per kg

- Large volume pricing can be up to 30% lower

Pricing depends on purity, particle size, order quantity, production method and customization requirements.

Pure Aluminum Powder Suppliers

Pure Aluminum Powder Suppliers

| Bedrijf | Plaats |

|---|---|

| Advanced Chemical Company | VS |

| Micron metalen | VS |

| Baohua Metal Materials | China |

| Hengxing Metallurgical | China |

| Shanghai ShuiDing Powder Material | China |

| Reade Geavanceerde Materialen | VS |

Selectiefactoren voor leveranciers:

- Purity levels and grades available

- Productiecapaciteit en doorlooptijden

- Average particle size ranges

- Customization of particle distribution

- Packaging options

- Pricing levels based on order quantities

- Compliance with international standards

Pure Aluminum Powder Handling and Storage

Pure Aluminum Powder Handling

| Aanbeveling | Reden |

|---|---|

| Use proper ventilation | Avoid concentrated dust environment |

| Employ grounding systems | Prevent static discharge during handling |

| Limit moisture exposure | Prevents oxidation of particles |

| Volg veilige protocollen | Verminder gezondheids- en brandgevaren |

| Ontstekingsbronnen vermijden | Flammable powder risk |

| Gebruik vonkvrij gereedschap | Voorkom de mogelijkheid van ontsteking |

Aanbevelingen voor opslag

- Store in dry, inert sealed containers

- Bewaar temperaturen onder 27°C

- Limit exposure to oxidizers like nitric acid

Proper precautions during handling and storage help preserve purity and prevent oxidation or ignition risks.

Pure Aluminum Powder Inspection and Testing

Pure Aluminum Powder Testing

| Test | Details |

|---|---|

| Chemische analyse | XRF or ICP testing verifies composition |

| Deeltjesgrootteverdeling | Laserdiffractieanalyse |

| Schijnbare dichtheid | Hall-flowmetertest volgens ASTM B212-standaard |

| Poedermorfologie | SEM-beeldvorming van deeltjesvorm |

| Analyse van de stroomsnelheid | Zwaartekrachtstroomsnelheid door gespecificeerde trechter |

| Vochtmeting | Verlies bij droogtest |

Testing ensures the powder meets the required purity levels, particle characteristics, density specifications, morphology and flowability per applicable standards.

Pure Aluminum Powder Pros and Cons

Advantages of Pure Aluminum Powder

- Low density provides lightweight properties

- Excellent electrical and thermal conductivity

- Goede corrosiebestendigheid

- High ductility and excellent formability

- Recyclebaar en milieuvriendelijk

- Cost-effective compared to other conductive powders

Limitations of Pure Aluminum Powder

- Low strength limits load bearing structural applications

- Moderate high temperature mechanical strength

- Requires protective coatings in corrosive environments

- Sensitive to contamination from moisture and other powders

- Pyrophoric nature requires careful handling

- Gradually oxidizes over time if uncoated

Comparison With Al-Mg Alloy Powder

Pure Al vs Al-Mg Alloy Powder

| Parameter | Zuiver Al | Al-Mg |

|---|---|---|

| Dikte | 2,7 g/cc | 2,7 g/cc |

| Kracht | 90-100 MPa | 150-220 MPa |

| Geleidbaarheid | Uitstekend | Goed |

| Corrosieweerstand | Goed | Uitstekend |

| Kosten | Laag | Hoog |

| Toepassingen | Thermite welding, pyrotechnics | Structural components |

- Pure Al offers better conductivity and lower cost

- Al-Mg alloy provides higher strength

- Pure Al suited for electrical applications and pyrotechnics

- Al-Mg preferred for structural lightweight components

Pure Aluminum Powder FAQs

Q: What are the main applications of pure aluminum powder?

A: Main applications include thermite welding, conductive coatings, pyrotechnic compositions, diamond tools, metal injection molding of non-structural parts, and low-melting casting alloys.

Q: What precautions should be taken when working with pure aluminum powder?

A: Recommended precautions include proper ventilation, avoiding ignition sources, explosion-proof equipment, grounding systems, non-sparking tools, protective gear, safe protocols, and inert storage sealed away from contaminants.

Q: How does pure aluminum powder differ from aluminum alloy powders?

A: Pure aluminum has 99% or higher Al content while alloy powders contain other elements like magnesium, silicon, zinc. Pure Al offers high conductivity but lower strength than alloys.

Q: What affects the properties of pure aluminum powder components?

A: Key factors are apparent density, particle size distribution, compaction pressure, sintering parameters, impurities, and final part porosity.

Over Met3DP

product categorie

HETE VERKOOP

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Gerelateerde producten

Toonaangevende leverancier van oplossingen voor additieve productie, met hoofdkantoor in Qingdao, China.

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- info@metal3dp.com

- amy@metal3dp.com

- +86 19116340731