Cu 99,95 poeder

Cu 99,95 poeder, ook wel elektrolytisch tough pitch (ETP) koperpoeder genoemd, is een zeer zuiver koperpoeder met minimaal 99,95% koper. Het heeft een uitstekend elektrisch en thermisch geleidingsvermogen in combinatie met goede mechanische eigenschappen. Belangrijke toepassingen zijn elektrische contacten, borstels, lasproducten, hardsolderen, frictiematerialen en diamantgereedschappen.

Lage MOQ

Zorg voor een lage minimale bestelhoeveelheid om aan verschillende behoeften te voldoen.

OEM & ODM

Bied op maat gemaakte producten en ontwerpdiensten om aan de unieke behoeften van de klant te voldoen.

Voldoende voorraad

Zorg voor een snelle orderverwerking en bied een betrouwbare en efficiënte service.

Klanttevredenheid

Producten van hoge kwaliteit leveren waarbij klanttevredenheid centraal staat.

deel dit product

Inhoudsopgave

Overview of Cu 99.95 Powder

Cu 99.95 powder, also referred to as electrolytic tough pitch (ETP) copper powder, is a high purity copper powder containing a minimum of 99.95% copper.

It has excellent electrical and thermal conductivity combined with good mechanical properties. Key applications include electrical contacts, brushes, welding products, brazing, friction materials and diamond tools.

Some key properties and advantages of Cu 99.95 powder include:

Cu 99.95 Powder Properties and Characteristics

| Eigenschappen | Details |

|---|---|

| Samenstelling | 99.95% minimum copper |

| Dikte | 8.94 g/cc |

| Deeltjesvorm | Onregelmatig, hoekig |

| Maatbereik | 2-150 microns |

| Schijnbare dichtheid | Tot 50% ware dichtheid |

| Vloeibaarheid | Laag tot matig |

| Geleidbaarheid | Excellent electrical and thermal conductivity |

| Sinterbaarheid | Good sinterability in H2 atmosphere |

| Puurheid | High purity copper |

Cu 99.95 provides an optimal balance of conductivity, mechanical properties, sintering characteristics and cost for fabrication of parts via pressing and sintering.

Cu 99.95 Powder Composition

Typical composition of Cu 99.95 powder:

Cu 99.95 Powder Composition

| Element | Gewicht % |

|---|---|

| Koper (Cu) | 99.95% min |

| Zuurstof (O) | Maximaal 0,05% |

| Lead (Pb) | 0.005% max |

| Other impurities | 0.005% max |

- Copper provides excellent conductivity and ductility

- Oxygen present as impurity affects conductivity and sintering

- Lead and other impurities carefully controlled

High copper content gives excellent electrical and thermal conductivity combined with good mechanical properties after sintering.

Cu 99.95 Powder Physical Properties

Cu 99.95 Powder Physical Properties

| Eigenschappen | Waarden |

|---|---|

| Dikte | 8.94 g/cc |

| Smeltpunt | 1083°C |

| Warmtegeleiding | 400 W/mK |

| Elektrische weerstand | 1.72 μΩ-cm |

| Recrystallization temperature | 200-300°C |

| Curie-temperatuur | -269°C |

- High density compared to iron and aluminum

- Excellent thermal conductivity for heat removal

- Low electrical resistivity provides high conductivity

- Resistivity increases above Curie temperature

- Recrystallization enables sintering and improves ductility

The physical properties make Cu 99.95 suitable for applications like electrical contacts and brushes requiring high conductivity.

Cu 99.95 Powder Mechanical Properties

Cu 99.95 Powder Mechanical Properties

| Eigenschappen | Waarden |

|---|---|

| Treksterkte | 220-340 MPa |

| Opbrengststerkte | 70-190 MPa |

| Verlenging | 35-60% |

| Hardheid | 45-90 HB |

| Elasticiteitsmodulus | 110-130 GPa |

| Druksterkte | 500-700 MPa |

- Good combination of strength and high ductility

- Relatively low hardness and high malleability

- Moderate strength levels compared to high strength alloys

- Properties depend on factors like porosity and grain size

The mechanical properties make Cu 99.95 suitable for softer conductive components that require deformation and compressive strength.

Cu 99.95 Powder Applications

Typical applications of Cu 99.95 powder include:

Cu 99.95 Powder Applications

| Industrie | Toepassingsvoorbeelden |

|---|---|

| Electrical and electronics | Contacts, connectors, brushes, RF shielding |

| Automobiel | Brushes, bushings, bearings |

| Industrieel | Welding electrodes, casting molds, metal matrix composites |

| Productie | Brazing and soldering, tooling components |

| Friction products | Brake pads, clutch discs |

Enkele specifieke toepassingen:

- Sliding electrical contacts and brushes

- Structural components requiring conductivity

- Jewelry crafting and artisanal products

- Diamond tools with copper metal matrix

- Welding rods and brazing paste formulations

- Mold liners for casting reactive alloys

The excellent balance of conductivity, mechanical properties, formability and cost make Cu 99.95 suitable for this broad range of applications.

Cu 99.95 Powder Specifications

Key specifications for Cu 99.95 powder include:

Cu 99.95 Powder Specifications

| Standaard | Beschrijving |

|---|---|

| ASTM B602 | Standard specification for undeformed, wrought, electrolytic tough pitch copper |

| JIS H3125 | Electrolytic copper and copper alloy powders |

| ISO 3497 | Copper powders for general purposes |

| ASTM B Guidance | Apparent density, flow rate, particle size distribution |

Deze normen definiëren:

- Minimum 99.95% copper content

- Limits on impurities like O, Pb

- Required powder characteristics

- Production method – electrolytic process

- Aanvaardbare deeltjesgrootteverdeling

- Testing methods for powder properties

Compliance ensures the powder meets the required purity and properties for the intended application.

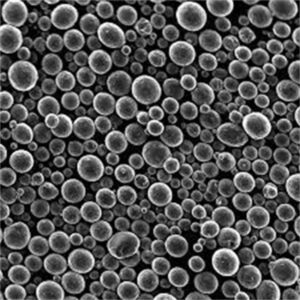

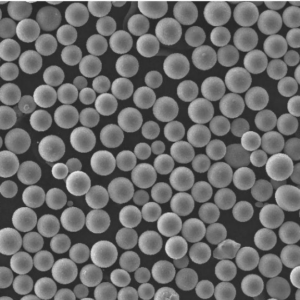

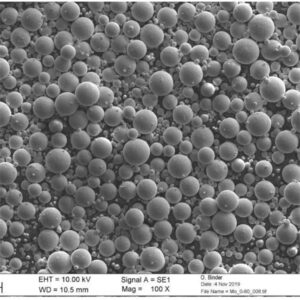

Cu 99.95 Powder Particle Sizes

Cu 99.95 Powder Particle Size Distribution

| Deeltjesgrootte | Kenmerken |

|---|---|

| 2-20 microns | Very fine powder used in microelectronics |

| 5-30 microns | Fine powder for sintering and injection molding |

| 15-150 micron | Coarse powder suitable for pressing |

- Finer powder sizes provide greater sintered density

- Coarse powder has better flowability for automated filling

- Size range tailored based on part requirements

- Both irregular and spherical powder shapes are available

Controlling particle size distribution allows optimizing pressing characteristics, sintered density and properties.

Cu 99.95 Powder Apparent Density

Cu 99.95 Powder Apparent Density

| Schijnbare dichtheid | Details |

|---|---|

| Tot 50% ware dichtheid | Voor onregelmatige poedermorfologie |

| 3.5-5.0 g/cc typical | Compacts to nearly full density after pressing and sintering |

- Higher apparent density improves powder flow and compactibility

- Onregelmatige morfologie beperkt de maximale pakkingsdichtheid

- Waarden tot 60% zijn mogelijk met geoptimaliseerd bolvormig poeder

- High green density after compaction enables good sintering

Higher apparent density improves manufacturing productivity and part quality.

Cu 99.95 Powder Production Method

Cu 99.95 Powder Production

| Methode | Details |

|---|---|

| Elektrolyse | Copper cathodes dissolved anodically into Cu+ ions which are deposited onto stainless steel cathodes |

| Slijpen | Coarse powder broken down and classified into specific size ranges |

| Gloeien | Softens the powder particles and improves compressibility |

| Reducing atmosphere | Prevents oxidation of particles during production |

- Automated electrolytic process allows high purity powder production

- Grinding and sieving provides controlled particle size distribution

- Annealing enables easy compaction into high density parts

- Strict process control ensures reliable and consistent powder quality

Cu 99.95 Powder Pricing

Cu 99.95 Powder Pricing

| Factor | Impact op de prijs |

|---|---|

| Zuiverheidsgraad | Hogere zuiverheidsgraden kosten meer |

| Deeltjesgrootte | Ultrafine is more expensive |

| Bestelhoeveelheid | Price decreases with bulk orders |

| Productie methode | Additional processing increases cost |

| Verpakking | Special packaging like vacuum sealing adds cost |

Indicatieve prijzen

- Cu 99.95 fine powder: $8-12 per kg

- Cu 99.95 coarse powder: $7-10 per kg

- Reduced pricing applicable for bulk orders >500 kg

Pricing depends on order volume, particle size, production method, purity level and packaging.

Cu 99.95 Powder Suppliers

Cu 99.95 Powder Suppliers

| Bedrijf | Plaats |

|---|---|

| Kymera International | VS |

| GGP Metalpowder | Duitsland |

| American Chemet Corporation | VS |

| Shanghai CNPC Powder Material | China |

| Nuclead | Frankrijk |

| Libo Metals | China |

Selectiefactoren voor leveranciers:

- Powder purity levels and grades offered

- Productiecapaciteit en doorlooptijden

- Average particle size ranges

- Customization of size distribution

- Packaging and minimum order quantity

- Prijsniveaus gebaseerd op ordervolume

- Compliance with international specifications

Cu 99.95 Powder Handling and Storage

Cu 99.95 Powder Handling

| Aanbeveling | Reden |

|---|---|

| Vermijd inademing | Potential respiratory irritation |

| Use masks, gloves | Prevent ingestion |

| Zorg voor voldoende ventilatie | Reduce airborne particles |

| Ontstekingsbronnen vermijden | Brandbaar stofgevaar |

| Follow anti-static procedures | Voorkom brand door statische ontlading |

| Gebruik vonkvrij gereedschap | Avoid ignition during handling |

| Store in cool, dry location | Prevent oxidation and moisture absorption |

Aanbevelingen voor opslag

- Store in sealed containers away from acids or chlorides

- Houd de temperatuur onder de 27°C

- Limit exposure to:

- Oxidizing acids like nitric acid

- Hot sulfuric acid

- Hydrogen sulfide

- Ammonia solutions

- Chlorinated hydrocarbons

Proper handling and storage helps preserve purity and prevent reactivity or fire hazards.

Cu 99.95 Powder Inspection and Testing

Cu 99.95 Powder Testing

| Type test | Details |

|---|---|

| Chemische analyse | ICP analysis to verify composition |

| Deeltjesgrootteverdeling | Laserdiffractieanalyse |

| Schijnbare dichtheid | Hall flowmeter test per ASTM B212 |

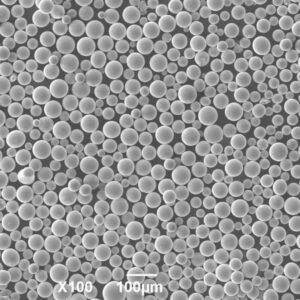

| Poedermorfologie | SEM-beeldvorming |

| Tik op dichtheid | Measured after mechanical tapping |

| Analyse van de stroomsnelheid | Zwaartekrachtdebiet door gespecificeerd mondstuk |

Stringent testing ensures the powder meets chemical, physical and morphological specifications required for the application.

Cu 99.95 Powder Pros and Cons

Advantages of Cu 99.95 Powder

- Excellent electrical and thermal conductivity

- Good ductility and malleability

- Cost-effective compared to pure silver or gold

- Good corrosion resistance and bio-compatibility

- Easy to sinter and compress into high density parts

- Recyclebaar en milieuvriendelijk

Limitations of Cu 99.95 Powder

- Lower strength than high strength alloys

- Matige oxidatieweerstand bij hoge temperaturen

- Heavy compared to magnesium and aluminum

- Not suitable for highly stressed load-bearing components

- Surface tarnishing over time if uncoated

- Restricted food contact applications

Comparison With CuCrZr Powder

Cu 99.95 vs CuCrZr Powder

| Parameter | Cu 99.95 | CuCrZr |

|---|---|---|

| Dikte | 8.94 g/cc | 8.8 g/cc |

| Kracht | 220-340 MPa | 450-650 MPa |

| Geleidbaarheid | Uitstekend | Gematigd |

| Thermische stabiliteit | Eerlijk | Uitstekend |

| Kosten | Laag | Hoog |

| Toepassingen | Electrical, thermal,moderate load | High strength structural parts |

- Cu 99.95 has better conductivity and lower cost

- CuCrZr provides higher strength and thermal stability

- Cu 99.95 suitable for softer conductive components

- CuCrZr preferred for high load structural parts

Cu 99.95 Powder FAQs

Q: What are the main applications of Cu 99.95 powder?

A: The main applications include electrical contacts, brushes, welding products, diamond tools, brazing alloys, friction materials, and metal matrix composites. It is widely used in electronics, automotive and industrial products.

Q: What affects the properties of Cu 99.95 powder parts?

A: Key factors affecting properties are apparent density, amount of lubricant, compacting pressure, sintering time/temperature, powder composition, particle size distribution, and presence of impurities.

Q: What precautions should be taken when handling Cu 99.95 powder?

A: Recommended precautions include avoiding inhalation, ensuring proper ventilation, wearing protective gear, controlling static discharge, using non-sparking tools, avoiding ignition sources, and storing in a cool, dry location in sealed containers.

Q: How does Cu 99.95 powder differ from bronze and brass powders?

A: Bronze and brass are copper alloys with tin and zinc while Cu 99.95 is pure copper. It has higher conductivity but lower strength than bronze or brass. Cu 99.95 is more cost-effective.

Over Met3DP

product categorie

HETE VERKOOP

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Toonaangevende leverancier van oplossingen voor additieve productie, met hoofdkantoor in Qingdao, China.

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- info@metal3dp.com

- amy@metal3dp.com

- +86 19116340731