niobium titanium poeder is an advanced intermetallic material with excellent superconducting properties and high strength. This article provides a comprehensive overview of NbTi powder including its composition, production methods, key properties, applications, specifications, pricing, and more.

Overview of niobium titanium powder

NbTi is an intermetallic compound composed of niobium (Nb) and titanium (Ti). It is considered a superconductor material, able to conduct electricity with zero resistance below a critical temperature. NbTi has higher strength compared to pure niobium and enhanced superconducting properties from the titanium additions.

Key properties that make NbTi useful for various high-tech applications are:

- High critical temperature

- High critical magnetic field strength

- Good ductility and workability

- Excellent strength

- Corrosieweerstand

- Biocompatibiliteit

NbTi powder can be compacted into various product forms from wire and tape to rods and specialty shapes. Key applications utilize the superconductivity such as for MRI machines, particle accelerators, tokamak fusion reactors, and high field magnets. The combination of strength and conductivity also suits NbTi for advanced medical devices, aerospace components, particle detectors, and energy storage.

Samenstelling of niobium titanium powder

The niobium content typically ranges from 40-75% with the balance being titanium. Specific compositions are tailored to meet required properties and performance requirements for different applications.

Typical Chemical Composition

| Element | Gewicht % |

|---|---|

| Niobium (Nb) | 40-75% |

| Titaan (Ti) | Evenwicht |

Trace amounts of tantalum, oxygen, carbon and nitrogen at ppm levels may be present. Specific limits depend on material form and end use application specifications.

Fasen

The microstructure of NbTi consists of a solid solution BCC niobium phase with titanium atoms randomly distributed throughout the lattice sites. Upon sufficient cold working and proper heat treatment, the material forms finely dispersed precipitates of the intermetallic NbTi phase coherent with the niobium matrix.

This two phase mixture leads to enhanced flux pinning properties which maximize performance in superconducting applications requiring high critical current density.

Productie of niobium titanium powder

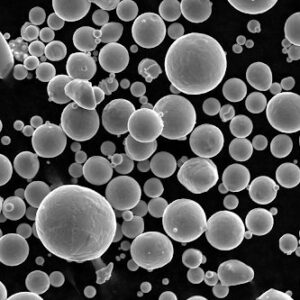

Commercial production methods for niobium titanium powder include vacuum induction melting followed by gas atomization or hydride-dehydride processing. The powder production route, parameters and post-processing are critical to achieving the right microstructure.

Vacuüm-inductie smelten

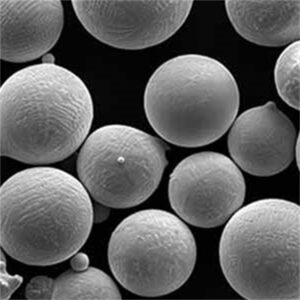

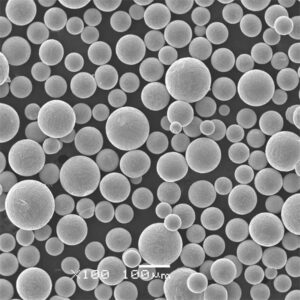

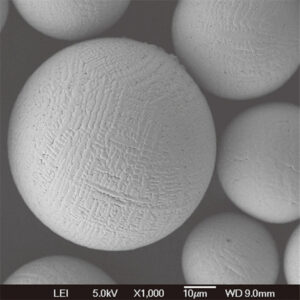

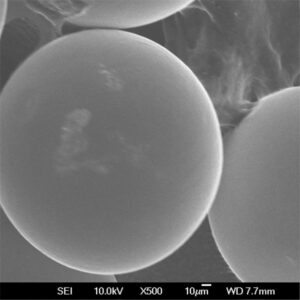

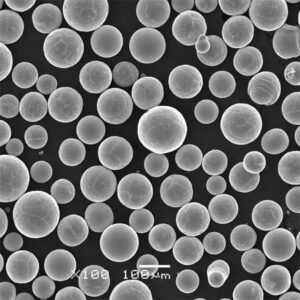

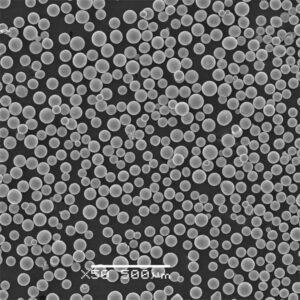

High purity niobium and titanium are induction melted in water-cooled copper crucible under vacuum. The melt is then poured into a cascading nozzle atomization system where it is atomized by inert argon gas jets. This produces fine spherical powder ideal for compaction into various shapes.

Atomization process parameters can be optimized to produce powder with mean particle sizes ranging from 25 microns to 150+ microns. Finer powders offer higher surface area for filtration efficiency whereas coarser powders benefit compaction density for products like wire.

Hydride-Dehydride

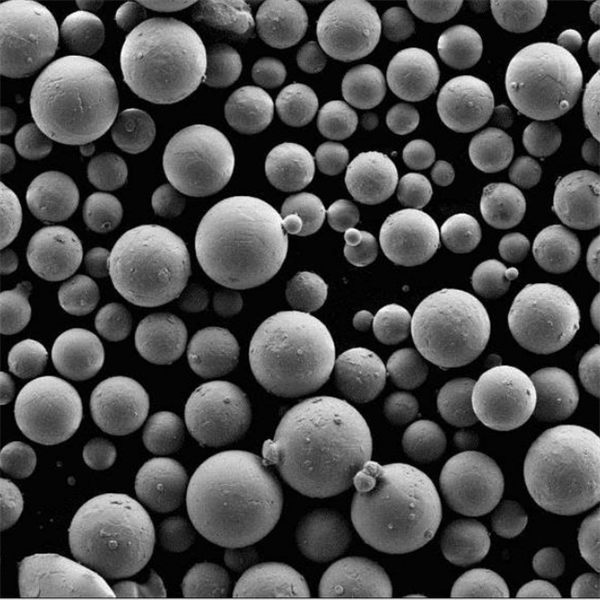

In this process, an ingot of NbTi is hydrided which embrittles it for crushing into a powder. The resulting hydride powder is then dehydrided under vacuum, leaving fine NbTi powder suitable for consolidation.

Hydride powders are more angular and irregular in shape but flow well for pressing and offer high chemical purity. This process can also be used to recycle scrap NbTi byproducts into powder feedstock.

Nabewerking

Secondary processing of the raw powder such as jet milling to narrow distribution or spherical annealing to improve morphology is used in some cases before compaction. High temperature vacuum sintering up to 2000°C ensures a fully dense material before mechanical working.

Eigenschappen van niobium titanium poeder

NbTi possesses excellent conductivity, magnetic properties, strength and workability due to its unique two phase composition.

Superconducting Properties

NbTi exhibits superconductivity below a critical temperature that depends on the exact alloy composition but is generally around 10K. This makes it well suited to liquid helium cooled applications.

It is categorized as a Type II superconductor having mixed state properties. This gives NbTi the highest critical magnetic fields and critical current density among practical superconductors near absolute zero.

Key Superconducting Properties

| Eigendom | Waarden |

|---|---|

| Critical Temperature (Tc) | 9 – 11 K |

| Critical Magnetic Field (Hc2) | 12 – 15 Tesla |

| Critical Current Density (Jc) | 3000 A/mm2 @ 5T, 4.2K |

Mechanische eigenschappen

In addition to the superconducting capability, NbTi has relatively high strength thanks to the two phase niobium-NbTi mixture. Exact properties depend on the processing history.

Room Temperature Mechanical Properties

| Eigendom | Waarden |

|---|---|

| Dikte | 6.2 – 6.5 g/cc |

| Ultieme treksterkte | 500 - 800 MPa |

| Opbrengststerkte (0,2% offset) | 400 - 600 MPa |

| Elasticiteitsmodulus | 52 – 69 GPa |

| Verlenging | 10 – 25% |

| Hardheid | 150 – 300 HV |

It retains moderate ductility for working into wire or tapes but has significantly higher strength than pure superconductors like niobium titanium.

Proper heat treatment such as aging at 400 ̊C is used to maximize the fine precipitate formation for peak strength and flux pinning to maintain conductivity through filaments.

Fysieke eigenschappen

Room Temperature Physical Properties

| Eigendom | Waarden |

|---|---|

| Elektrische weerstand | 15 – 25 μΩ-cm |

| Dikte | 6.2 – 6.5 g/cm3 |

| Smeltpunt | 2350 – 2500°C |

| Warmtegeleiding | 4-6 W/mK |

| Specific Heat Capacity | 265 J/kgK |

Toepassingen of niobium titanium powder

The main applications for niobium titanium powders fall into two primary categories:

- Superconducting magnet applications

- Advanced medical implants and devices

But research is ongoing into uses in particle accelerators, fusion energy, detectors, and specialty aerospace applications.

Superconducting Magnets

- MRI machine coils

- High field research magnets ≥10T

- Particle accelerators – beam transport/focusing

- Fusion tokamak electromagnets

- Magnetic separation

- Magnetic energy storage inductors

For these applications, NbTi wire and tapes are used to make powerful electromagnets cooled by liquid helium to temperatures under 10K to induce persistent, high density supercurrents with 12-15+ Tesla fields.

Medical Applications

- Orthodontic archwires

- Tandheelkundige implantaten

- Bone fixation plates

- Cardiovascular stents

- Surgical implants (non-magnetic)

The excellent strength, ductility, and biocompatibility coupled with being non-magnetic and non-interacting makes NbTi suitable for osteosynthesis devices as well as advanced cardiology stents for less risk of inflammation or rejection.

Research is also looking at NbTi for vascular graft tubing, spinal correction rods and electrical stimulation electrodes leveraging its conductive properties.

niobium titanium poeder Specificaties

NbTi powder and wire products meet various formal specifications from organizations such as ASTM International, European Pharmacopeia, and internal manufacturer and application standards.

Poederspecificaties

Key powder quality metrics:

- Deeltjesgrootteverdeling

- Powder morphology – spherical vs angular

- Schijnbare dichtheid en kraan dichtheid

- Purity levels – O2, H2, N2

- Superconducting properties

ASTM International has standardized test methods for measuring these powder characteristics. For example:

| Standaard | Titel | Test methode |

|---|---|---|

| ASTM B939 | Standard Test Method for Radial Crush Strength of Powder Metallurgy (PM) Bearing and Structural Materials | Compressibility / shape retention of powder particles |

| ASTM B243 | Standard Terminology of Powder Metallurgy | Definitions of common powder metallurgy terms |

Wire Specifications

Key metrics for NbTi wire include:

- Wire diameter and tolerance

- Extra low interstitial impurity levels

- Residual resistivity ratio (RRR)

- Critical temperature

- Critical magnetic field

- Critical current density

Superconducting wire is manufactured to stringent cleanliness standards for aerospace and military applications defined in SAE-AMS and U.S. Military specifications covering composition, contamination limits, testing procedures, and quality assurance requirements.

For example – AMS-WWK-5846H covers Corrosion and Heat-Resistant Niobium Alloys in the form of bars, billets, forgings, sheets, strips, and wire.

Leveranciers en prijzen

Niobium titanium powder and wire is only produced by a handful of specialist suppliers given the niche high-tech applications and specialized production equipment required.

Leading NbTi Powder Suppliers

- Wah Chang (US)

- Ningxia Orient Tantalum Industry (China)

- HC Starck (Germany)

- Phelly Materials (Netherlands)

Prijzen

As a specialty pulverized intermetallic material, niobium titanium poeder commands premium pricing relative to common metals. Cost per 100g can range from around $250 to $500+ depending on purity and particle characteristics.

Scrap and recycled NbTi powder is traded at discounts of 40% or more compared to virgin powder price levels.

In alternative forms like wire, a 1 kg spool of superconducting NbTi wire sells for $3,000 to $5,000+ depending on strand count and processing.

Comparisons With Other Materials

Niobium Titanium vs Niobium Tin

Niobium-tin (Nb3Sn) is another common superconductor competing with NbTi depending on the application. Compared to NbTi , Nb3Sn has:

Voordelen

- 50% higher critical magnetic field strength

- Ability to retain superconductivity at higher temperatures

Nadelen

- More complex manufacturing

- More brittle with lower workability

- More expensive (contains expensive tin)

This makes Nb3Sn more suitable to ultra high field magnets that justify the higher cost while NbTi offers the best well-rounded performance for general applications below 12T field strength.

Niobium Titanium vs Niobium Zirconium

Replacing some of the titanium in NbTi alloys with zirconium creates NbZr superconductors with slightly better ductility and workability. Key differences versus standard NbTi grades are:

NbZr Advantages

- Higher ductility – better for complex wire drawing

- Higher workability at low temps

- Less magnetic flux pinning centers

NbTi Advantages

- Lower materials cost

- Higher temperature stability

- Higher critical current density

So NbZr competes again for specialized high-field magnet coils pushing performance boundaries while NbTi offers the better economics and well-proven commercial properties meeting most medical or industrial needs.

Limitations and Risks

Despite the high performance as a superconductor, limitations of using niobium titanium include:

Kosten

- Expensive specialty material costing over $250 per 100g in powder form. This limits applications to high value industries.

Brittleness

- Prone to cracking if overworked/strained due to intermetallic phases present

- Annealing needed to retain ductility during manufacture

Oxidation

- Powder and wire oxidizes readily above 400°C

- Performance decays under oxidizing acids/conditions

Magnetic Field Limits

- Critical field caps out around 12-15T limiting achievable field strength

- Very fine multi-filament wire construction needed to reduce hysteresis losses in AC operation

Proper powder production, handling, and compaction as well as wire drawing practices mitigate these issues for reliable performance.

Outlook

Global demand for niobium-titanium is projected to grow steadily at 6-8% annually driven mainly by MRI machine production and upgrades but also from expansion in particle colliders for research.

Growth potential also exists in magnetic separation for mining applications and improvements in high temperature superconductors for next generation compact fusion power if the technology continues to progress to commercial viability.

With high barriers to entry, existing NbTi suppliers are positioned well to benefit from increasing consumption across medical, scientific, and potential future energy sectors. Recycling of scrap NbTi also helps supplement primary powder output.

Veelgestelde vragen

What is niobium titanium powder used for?

- Mainly used for manufacturing superconducting wire and tapes for high-field MRI magnets, particle accelerators, fusion reactors, specialty industrial magnets, etc. Also used for medical implants and devices due to its biocompatibility, strength, and non-magnetic properties.

What are the typical niobium and titanium percentages in NbTi?

- The niobium content by weight ranges from 40-75% with titanium accounting for the balance. Actual compositions vary by application to optimize properties – for example higher Nb for higher temperature stability.

What is the powder production method for NbTi powder?

- Main production routes are gas atomization of induction melted ingots or via hydride-dehydride processing to crush and pulverize scrap/ingots into powder. Both methods produce the necessary small grained microstructure.

What is the critical temperature of NbTi?

- Critical temperature where NbTi transitions to a superconducting state is between 9-10.5K depending on exact composition. This makes it well-suited to liquid helium cooling applications.

What are other common niobium-based superconductors?

- NbTi is most common but niobium-tin (Nb3Sn) offers higher field strength capabilities for specialized magnets. Less common is niobium-zirconium (NbZr) with some ductility advantages but lower overall conductivity than NbTi at near absolute zero temperatures.

Is niobium titanium a type I or type II superconductor?

- NbTi is categorized as a type II superconductor, meaning it exhibits both normal and superconducting states in parallel in an applied magnetic field between its first and second critical field strengths. This gives a high critical current density.

Is NbTi degradation a concern?

- Performance decay from oxidation can be an issue above 400°C. Maintaining a protective inert atmosphere is important during powder processing and wire manufacturing. Insulating NbTi wire in epoxy matrix helps guard against oxidation during service.