Poeders van metaallegeringen refer to particulate blends of two or more metal elements used across manufacturing, additive techniques and research applications. This guide serves as an in-depth reference on metal alloy powders – exploring types, production methods, key properties, specifications, suppliers, pricing, applications, comparisons and more.

Overzicht van poeders voor metaallegeringen

Metal alloy powders comprise metallic blends tailored to achieve enhanced properties over single-element metals. Key attributes:

- Composition: 2+ metals in defined ratios

- Production: Atomization, electrolysis, reduction etc.

- Form: Fine particulate powder

- Common types: Steels, titanium, aluminum, nickel, cobalt alloys

- Key traits: Heat and wear resistance, durability, strength

By combining complimentary metals in optimized stoichiometries, powder metallurgy facilitates tunable alloys unattainable via conventional processes – lending advanced utility across industries.

Metal Alloy Powder Types

Major Categories:

- Steel alloys – stainless, tool, alloy steels…

- Titanium legeringen – Ti6Al4V, TiAl, titanium aluminides

- Aluminium legeringen – aluminum 2024, 7075, AlSiMg

- Kobaltlegeringen – cobalt chrome, MP35N

- Nikkel legeringen – Inconel 625, Inconel 718, Hastelloys

And uniqueness based on:

Legerende elementen

| Type | Common Elements | Example Materials |

|---|---|---|

| Low Alloy | <5% Ni, Cr, Mo | 4140, 4340 |

| Medium Alloy | 5-15% Ni, Cr, Mo etc. | H13, 420 stainless |

| High Alloy | 15-30% Al, Co, Ti etc. | 316 stainless, MP35N |

Productie methode

| Methode | Alloy Systems | Kenmerken |

|---|---|---|

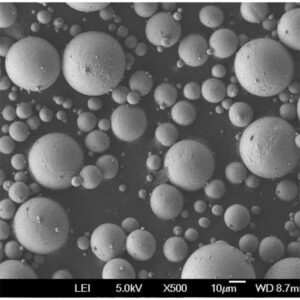

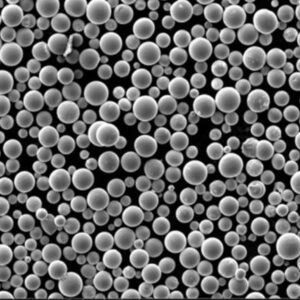

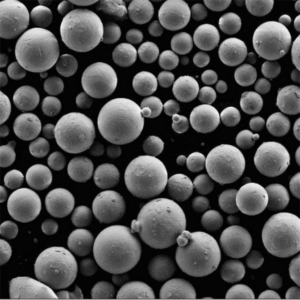

| Gas Atomized | De meeste legeringen | Spherical, controlled size distribution |

| Water Verstoven | Staal | Irregular shape, wide distribution |

| Plasma Verstoven | Reactive materials like Ti & Al alloys | Controlled atmosphere, spherical |

| Elektrolytisch | Copper, Ni | Dendritic flakes, sponge |

Blending elements like aluminum, cobalt, chromium, tungsten etc. with base metals produces enhanced alloy powder capabilities. Production technique also influences powder morphology and traits.

Metal Alloy Powder Manufacturing Processes

Gasverstuiving

- Inert gas disintegrates molten metal stream into fine droplets

- Facilitates small, spherical powder ideal for AM

Waterverneveling

- High pressure water breaks up metal melt into powders

- Lower cost but less control than inert gas

Plasma-verneveling

- Electrode dissociates reactive melts like Ti alloys in controlled atmosphere

Elektrolyse

- Electrochemical dissolution of metals into powdered forms

Tailoring process dynamics like thermal profiles, gas/fluid flows and chemical conditions allows tuning particle size distribution, grain morphology and internal microstructures to match application requirements.

Eigenschappen van Poeders van metaallegeringen

Fysieke eigenschappen

| Attribuut | Kenmerken |

|---|---|

| State | Solid Particulate Powder |

| Kleur | Greyish silver/black powder |

| Magnetisme | Ferritic/martensitic materials are ferromagnetic |

| Odor | Typically odorless |

| Taste | Tasteless |

| Solubility | Insoluble in water and common solvents |

Mechanische eigenschappen

| Metrisch | Beschrijving |

|---|---|

| Hardheid | Range from soft precious alloys < 100 HV to hardened tool steels > 700 HV |

| Kracht | Span from < 100 MPa for plain carbon steels to over 2,000 MPa for some nickel superalloys |

| Ductiliteit | Measure of malleability – high for C steel, medium in work steels, low in high Cr/Co materials |

Thermische eigenschappen

| Measure | Details |

|---|---|

| Smeltpunt | Dependent on alloy system – 500 to 1500°C+ |

| Warmtegeleiding | 15 – 90 W/mK between alloy types |

| CTE | Varies from ~5 x10-6 K-1 (Invar) to ~18 x10-6 K-1 (aluminum alloys) |

Tafel 2: Overview of common metal alloy powder physical, mechanical and thermal properties

Specific alloy choice balances hardness, yield strength, ductility, density, heat/corrosion resistance and other attributes as per application.

Specificaties

Commercial metal alloy powders are tested and certified to specifications:

Deeltjesgrootteverdeling

| Standaard | Microns | Productie methode |

|---|---|---|

| Prima | 1-25 | Gasverneveling |

| Medium | 25-75 | Gasverneveling |

| Ruw | 75-150 | Waterverneveling |

Zuiverheidsgraden

| Rating | Chemistry Control | Onzuiverheden |

|---|---|---|

| Standaard | Broad alloy ranges | Up to 1% other |

| Aangepast | Fixed alloy target | <1000 ppm impurities |

| Hoge zuiverheid | Tight alloy band | <100 ppm contaminants |

Tafel 3: Typical size ranges, chemistry and purity grades for commercial metal alloy powders

Meeting or exceeding certified specifications ensures repeatable performance between powder lots and downstream production runs.

Metal Alloy Powder Manufacturers

Providers specializing in niche alloy formulations:

Steel & Iron Alloys

- Höganäs – atomized diffusion alloys

- Rio Tinto Metal Powders – water atomized alloys

Titanium & Aluminum Alloys

- AP&C – plasma atomization

- Tekna Advanced Materials – gas atomized spherical

Cobalt, Nickel & Exotic Alloys

- Sandvik Osprey – control melted small lots

- Tekna Advanced Materials – high purity medical/aerospace grades

And more generalists offering broader catalog options:

| Bedrijf | Materialen | Prijsbereik |

|---|---|---|

| Praxair | Tool, stainless, superalloys | $14-215/kg |

| Timmerman poederproducten | tool, stainless, superalloys | $35-205/kg |

| LPW Tech | Al, Ti, Ni, Co alloys | $30-185/kg |

Tabel 4: Leading suppliers across common alloy groups

Prices fluctuate with compositions, lot quantities and testing requirements – get current quotes directly.

Toepassingen van Poeders van metaallegeringen

| Industrie | Toepassingen | Voordelen |

|---|---|---|

| Lucht- en ruimtevaart | Turbine blades, airframe components | High strength, heat resistance |

| Automobiel | Gearing, powertrain parts | Wear protection |

| Productie | Custom product tooling | Shorter development cycles |

| Olie gas | Seals, valve components, well tools | Durability improvements |

Tabel 5: Metal alloy powder enables high performance applications across sectors

Leveraging properties like heat tolerance, hardness and corrosion resistance facilitates reliability in demanding equipment environments over incumbent alternatives like plastics or traditional alloys.

Vergelijkende voor- en nadelen

Advantages of Metal Alloy Powders

- Better mechanical properties – strength, wear, heat etc.

- More easily processable into net shape parts vs wrought

- Shorter manufacturing and development timelines

- Improved microstructures from rapid solidification

Tradeoffs

- Higher materials costs than traditional fabrication grades

- Limited very large part production scale currently

- Lower throughput than high volume manufacturing

- Design complexity requiring modeling expertise

Specialized traits in optimized alloys offsets tradeoffs for industries valuing customization, properties and responsiveness.

Veelgestelde vragen

Q: What is the main difference between metal alloy ingots versus powders?

A: Powders impart refined, segregation-free microstructures and provide feedstock for emerging manufacturing techniques. Ingots serve conventional forming processes.

Q: Which metal alloy powder is expected to see the most growth in coming years?

A: Titanium and aluminum alloy powders for aerospace applications given exceptional strength-to-weight capabilities and processability.

Q: What particle size range works best for common metal alloy AM processing?

A: 15-45 microns provides good powder bed packing density and layerwise cohesion while avoiding challenges seen with ultrafine powders.

Q: How are metal alloy powders different from metal oxide or ceramic powders?

A: Metal alloy powders contain 2+ metallic elements forming substitutional mixes while oxides/ceramics involve ionic chemistry changes with profoundly different properties.

Conclusie

Optimized metal alloy powder compositions, microstructures and morphologies extends part fabrication, prototyping and performance possibilities across aviation, space, automotive and energy sectors – as documented here through property insights, manufacturing guidance, specification parameters and application examples. Please reach out with any other questions surrounding specialty alloy selection, procurement or processing.