Overzicht van metaalpoeders van hoge zuiverheid

High purity metal powders refer to metals processed into fine particulate form while minimizing contamination from oxygen, nitrogen, carbon, and other elements. Maintaining ultra-low impurity levels allows manufacturing of products like electronic conductors, magnetic materials, superalloys, and welding wires with tightly controlled chemistry.

Applications range from 3D printing to electronics to aerospace components. Typical high purity metals include nickel, cobalt, copper, aluminum alloys, as well as refractory metals like tungsten, molybdenum, and tantalum. Both elemental metals and master alloys with addition of alloying elements are covered at purity levels exceeding 99%.

High Purity Metal Powder Types

| Materiaal | Purity Levels | Productie methodes | Kenmerken | Toepassingen |

|---|---|---|---|---|

| Nikkel | Up to 99.998% | Carbonylproces | Excellent conductivity, magnetics | Electronics, batteries |

| Koper | Up to 99.999% | Elektrolyse | High electric and thermal conductivity | Welding wires, electronics |

| Kobalt | Up to 99.95% | Hydrometallurgy | Behoudt sterkte bij hoge temperaturen | Cutting tools, magnets |

| Wolfraam | Up to 99.99% | Waterstofreductie | Very high density, strength | Light bulb filaments, counterweights |

| Tantaal | Up to 99.997% | Het smelten van elektronenbundels | Uitstekende corrosieweerstand | Capacitors, medical implants |

| Aluminium legeringen | Up to 99.99% | Verneveling | Lichtgewicht, hoge sterkte | Aerospace components, automotive |

metaalpoeders van hoge zuiverheid Productie methodes

Key techniques for producing pure metal powders include:

- Elektrolyse: Used for Cu, Zn, Ni. Electroplating deposits pure metal onto cathodes which is scraped off as powder.

- Carbonylproces: Used for Ni, Fe, Co. Metal is volatized from ore using CO gas then decomposed to powder.

- Verneveling: Used for Al, Mg, Ti alloys. Rapid solidification of molten metal forms powder upon gas or water atomization.

- Waterstofreductie: Used for W, Ta, Nb, Mo. Metal oxides heated in H2 gas causes oxygen removal leaving pure powders.

- Plasma-verneveling: Used for reactive metals like Ti, Zr. Water interactions avoided by using plasma gas instead of water.

- Elektronenbundel smelten: Used for Ti, Ta. High purity ingots levitated in vacuum melted by an electron beam then rapidly solidified by dropping through chamber.

High Purity Metal Powder Characteristics

| Parameter | Details | Measurement Method |

|---|---|---|

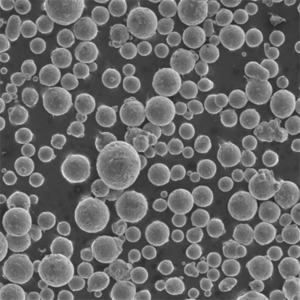

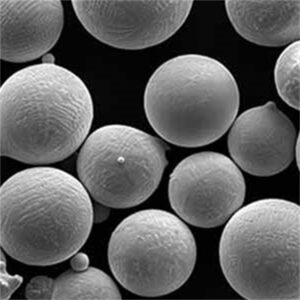

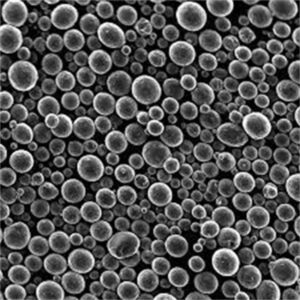

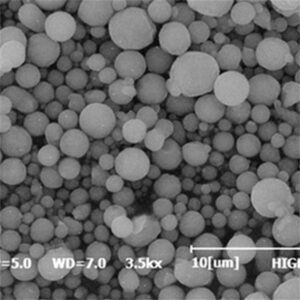

| Deeltjesgrootteverdeling | Varies from 10 μm to 150 μm | Deeltjesgrootteanalysator met laserdiffractie |

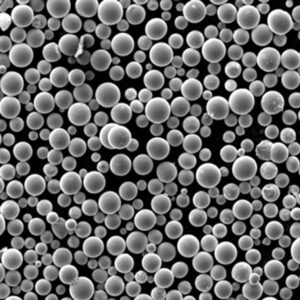

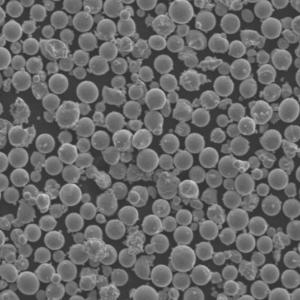

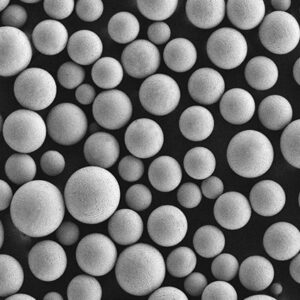

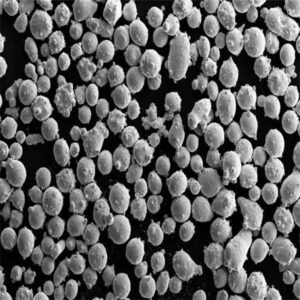

| Deeltjesvorm | Spherical, satellite, angular depending on production technique | SEM-beeldvorming |

| Dikte | Can approach theoretical density of the bulk material | Gaspyknometrie |

| Puurheid | Up to 99.999% via strict process controls and handling | ICP-OES chemische analyse |

| Impurity Elements | O, H, N, C most common contaminants | Combustion analysis followed by IR detection |

| Stroomkenmerken | Effects pourability, spreadability in AM machines | Hall flowmeter funnel test |

Applications of High Purity Metal Powders

| Industrie | Sollicitatie | Desired Powder Attributes |

|---|---|---|

| Additieve productie | 3D printing final parts | Controlled particle size distribution between 10-45 μm with good flow and packing is optimal |

| Elektronica | Conductive films, circuits, RF shielding | High purity above 99.9%, excellent conductivity, may require flake or dendritic powder |

| Welding Wires | Improved weld strength | Low oxygen content below 100 ppm preferred |

| Diamond Tools | Cobalt binder increases tool lifespan | High hardness, ability to take compressive loads without fracturing |

| Magneten | Improved residual induction | Chemical compatibility with rare earth metals for sintering |

| Medische apparaten | Corrosiebestendigheid, biocompatibiliteit | Purity helps avoid metal ion leaching which may cause biological reactions |

Benefits of High Purity Metal Powders

Using high purity metal powders enables:

- More consistent chemistry and microstructure batch-to-batch

- Achievement of electrical, magnetic, mechanical, and corrosion targets

- Lower contamination risks

- Attainment of strict aerospace and medical device standards

- Improved product performance and lifespans

- High value component production justifying increased powder cost

- Design flexibility – customize alloy ratios and powder attributes as needed

Challenges With High Purity Metal Powders

| Difficulty | Mitigating Actions |

|---|---|

| Higher Cost | Prioritize use only where function impacts justify premium price, minimize waste with stringent inventory controls |

| Limited Supply Chain | Plan production schedules accounting for longer lead times, qualify multiple vendors |

| Vochtgevoeligheid | Store powder under vacuum or inert gases, requalify batches for degradation after shelf life expiration |

| Handling Precautions | Eliminate iron contamination via use of non-magnetic tools, isolate from grinding or machining sources |

| Process Control | Perform extensive parameter optimization, measurement, and documentation to ensure repeatability |

metaalpoeders van hoge zuiverheid Prijzen

A cost comparison of Regular Grade vs High Purity nickel powder suitable for additive manufacturing is shown below:

| Parameter | Regular Nickel Powder | High Purity Nickel Powder |

|---|---|---|

| Puurheid | 98%-99% Ni | >99.95% Ni |

| Zuurstofgehalte | 0.4% | <0,01% |

| Koolstofgehalte | 0.1% | <0.02% |

| Sulfur Content | 0.01% | <0.005% |

| Deeltjesgrootte | 15 to 45 μm | 15 to 45 μm |

| Kosten per kg | $50 | $240 |

Despite the higher cost, industries like aerospace rely exclusively on high purity powder even for prototype builds to prevent quality issues in final application.

metaalpoeders van hoge zuiverheid Leveranciers

Some leading suppliers offering high purity metal powders for industries like additive manufacturing include:

| Bedrijf | Headquarters Location | Aangeboden materialen | Markets Served |

|---|---|---|---|

| Sandvik Visarend | Zweden | Ni, Co, Cu, Al, Ti, more | Additive manufacturing of end use components |

| AP&C | Canada | Ti, Ta, Nb Alloys, more | Aerospace, medical, industrial |

| Timmerman technologie | Verenigde Staten | Ni, Co, more | Consumer electronics, aerospace |

| Praxair | Verenigde Staten | Ta, Nb, Mo alloys | Capacitors, alloying agent |

| AMETEK | Verenigde Staten | Zr, Ti, W alloys | Military, aerospace, semiconductor |

metaalpoeders van hoge zuiverheid Kwaliteitsnormen

Key specifications relating to high purity metal powders include:

| Standaard | Toepassingsgebied | Parameters Covered |

|---|---|---|

| ASTM B809 | Standard for annealed high purity Cu powder production | Governs preparation method, chemical composition limits and impurities, particle size distribution, sampling |

| AMS-P-81748 | Ni powder used as additive manufacturing feedstock | Purity, particle attributes, recommended handling and processing parameters |

| ASTM F3049 | Guide for characterizing properties of AM metal powders | Test procedures for powder morphology, flow rate, density, reuse guidelines |

| ASTM F3056 | Specification for additive manufacturing Ni alloy powder | Chemical composition, contamination limits, particle size distribution, lot sampling |

These help ensure repeatable feedstock suited for demanding applications in aerospace, medical, electronics fields.

High Purity vs Regular Powders

| Parameter | High Purity Powder | Regular Powder |

|---|---|---|

| Puurheid | Up to 99.999% pure | 98-99% range |

| Samenhang | Tightly controlled chemistry within 0.01% | Can vary 1-3% batch-to-batch |

| Prestatie | Meets strict industry standards | Unreliable, variable results |

| Prijs | 4X to 10X higher | Lower cost per kg or pound |

| Doorlooptijd | Stock limitations, made to order in 10-12 weeks typically | Readily available off the shelf |

| Supply Chain | Single qualified vendor | Multiple vendor options |

| Toepassingen | Aerospace, medical, nuclear, electronics | Industrial prototypes, training builds |

So while high purity powders carry a significant price premium, their unmatched consistency and standards conformance justify use in mission-critical applications where product performance directly correlates with powder quality.

Veelgestelde vragen

| Vraag | Antwoord |

|---|---|

| Why is high powder purity important for metal 3D printing or additive manufacturing? | Impurities can alter local solidification rates leading to porosity or cracking that causes mechanical failure. Consistent chemistry and microstructure ensures repeatable material properties. |

| How are high purity levels achieved compared to conventional metal powders? | Additional process steps like vacuum induction melting, atomization under inert gases, prevent atmospheric contamination during production. Handling under argon atmosphere avoids moisture or oxygen pickup. |

| Does high purity powder confer better corrosion resistance properties? | Yes – contaminants often preferentially corrode leading to pitting. Reducing elements like sulfur, phosphorus, silicon to low ppm levels enhances corrosion resistance especially in acidic or saline environments. |

| Can you mix different purity level powders when printing a part? | In general powders should not be mixed since the different chemistries may negatively interact. Exceptions could be blending small ratios of master alloy powders to adjust the matrix composition. |

Samenvatting

High purity metal powders with minimized oxygen, nitrogen and other impurities enable fabrication of components meeting strict aerospace, defense, medical, electronics and nuclear applications. Maintaining elemental chemistry control below 100 ppm ensures reliable electrical, mechanical, and corrosion performance. Common high purity metals include nickel, cobalt, aluminum alloys and refractory metals like tungsten or tantalum. While cost per unit mass is 4X to 10X higher than conventional powders, high purity materials are essential for mission-critical parts where product quality directly correlates with powder quality starting from raw material. With continual improvements in purity reaching beyond 99.999%, high purity metal powders will enable the next generation of components powering electric vehicles, spacecraft, satellites, and medical devices.