High density tungsten powder possesses the greatest density among all metallic powders owing to tungsten’s extraordinarily high intrinsic density approaching that of gold. This unique attribute allows advanced design of compact, weight-efficient components across diverse sectors harnessing heavy powder pressing and sintering methodologies.

Overzicht of tungsten powder

With a density of 19.3 g/cm3 in solid form, tungsten packs immense weight into a tiny volume. By virtue of this, tungsten powder when compacted delivers unmatched density levels unachievable using any other material. Parts made from high-density tungsten powder find numerous applications in demanding environments.

Key drivers for utilizing high density tungsten powder include:

- High density similar to precious metals like gold, platinum

- Doubles the density available compared to lead, steel

- Enables heavy yet compact sizes and shapes

- Simple powder metallurgy route to end-use items

- Tailorable properties by mixing alloying elements

- Recyclability of high-value tungsten

Applications capitalizing on density span ballasts, radiation blocking, inertia, weighting of composites, vibration damping, and component miniaturization.

Types of High Density Tungsten Powder

While all tungsten powder varieties offer high density, certain grades and compositions impart optimal density levels after forming and sintering:

| Type | Beschrijving | Typical Density |

|---|---|---|

| Zuiver wolfraam | Higher purity above 99.95% ensures reliable density | ≥18 g/cm |

| Doped tungsten | Small rare earth oxide additions like Y2O3 improves sintered density | ≥18.5 g/cm |

| Tungsten-nickel-iron | Ni-Fe alloying provides excellent final density | ≥18 g/cm |

| Wolfraam zware legeringen | 90-97% W with Ni-Cu-Fe binder phases | ≥17.5 g/cm |

| Tungsten composites | Mixes with gold, tantalum, depleted uranium etc. | up to 21 g/cm |

These enhanced formulations expand high-performance options beyond pure tungsten to tailored property combinations.

Samenstelling of tungsten powder

High purity tungsten powder suitable for the highest possible density contains over 99.95% tungsten with only minor residual impurities:

| Element | Maximum Content | Rol |

|---|---|---|

| Wolfraam (W) | 99.95% | Principal component |

| Koolstof (C) | 100 ppm | Grain growth inhibitor |

| Zuurstof (O) | 100 ppm | Oppervlakteoxide |

| Koper (Cu) | 10 ppm | Residual trace impurity |

| Silica (Si) | 20 ppm | Impurity |

Specialized heavy alloy grades have deliberate alloying additions like nickel, copper, iron etc. along with tungsten to enhance properties further.

Eigenschappen of tungsten powder

High density tungsten powder enables manufacture of near-net-shape parts boasting extreme density coupled with useful strength, hardness and thermal properties.

Fysieke eigenschappen

| Eigendom | Waarde |

|---|---|

| Dikte | ≥18 g/cm<sup>3</sup> |

| Smeltpunt | 3380-3410°C |

| Kracht | Up to 1000 MPa |

| Hardheid | ≥400 VPN |

| Warmtegeleiding | ∼175 W/(m·K) |

| Uitzettingscoëfficiënt | ∼4.5 μm/(m·K) |

These characteristics stem from tungsten’s intrinsic atomic structure and make it ideal for high-density applications needing thermal-mechanical integrity.

Mechanische eigenschappen

Careful powder pressing and sintering imparts advantageous mechanical properties:

| Eigendom | Waarde |

|---|---|

| Hardheid | Up to 550 VPN |

| Opbrengststerkte | ∼900 MPa |

| Treksterkte | Up to 1000 MPa |

| Verlenging | ∼10% to 15% |

| Breuktaaiheid | ∼20 MPa√m |

| Vermoeidheid Sterkte | 500 MPa |

Alloying elements like nickel, iron etc. help tailor ductility, toughness and machining characteristics.

Physical Attributes

Salient physical attributes of high density tungsten powder useful for designers:

| Parameter | Waarde | Unit |

|---|---|---|

| Dikte | 18 to 19.3 | g/cm<sup>3</sup> |

| Elektrische weerstand | 5.5 | μΩ·cm |

| Warmtegeleiding | 170 | W/(m·K) |

| Smeltpunt | 3410 | °C |

| Kookpunt | 5930 | °C |

| Specifieke hitte | 132 | J/(kg·K) |

The ultrahigh melting point and thermal conductivity ensure retention of strength and dimensional integrity at extreme temperatures.

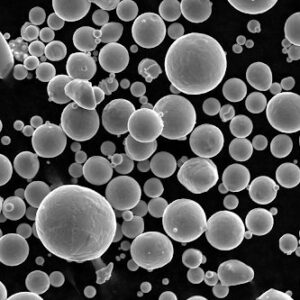

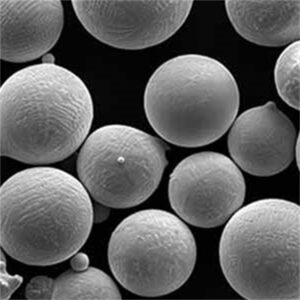

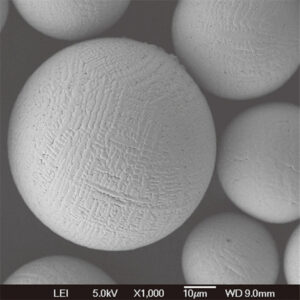

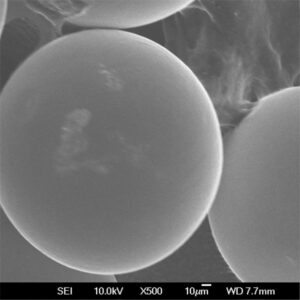

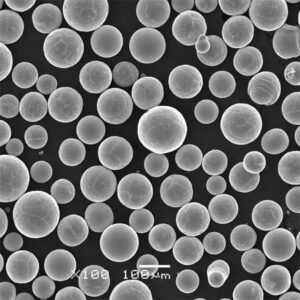

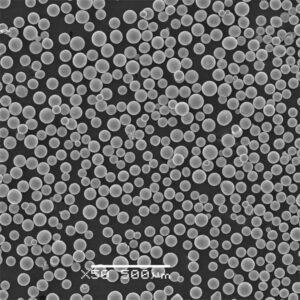

Productie of tungsten powder

High density tungsten powder is manufactured by the hydrogen reduction of tungsten oxide combined with particle size reduction:

1. Ore concentration – Natural tungsten ore is physically processed to higher grades

2. Conversion to oxide – Alkaline digestion and calcining yields WO<sub>3</sub>

3. Hydrogen reduction − 800°C reduction of oxide produces tungsten powder

4. Milling and classification – Controlled milling and air classification yield fine powders

5. Mixing and doping – Pure grades are blended with grain growth inhibitors or alloying elements

6. Packaging – Sealed drums or bags preserve morphology during shipment

High chemical purity, excellent particle size distribution, good powder flow and consistent powder properties help achieve maximum final density.

Toepassingen of tungsten powder

Some major application areas benefitting from high density tungsten powder include:

Counterweights and ballast

Excellent dimensional stability and corrosion resistance couple with density for balancing wheels, gyroscopes, actuators etc.

Stralingsafscherming

Tungsten alloys provide economical gamma and x-ray shielding for nuclear, medical, aerospace and electronics uses.

Trillingsdemping

Introducing heavy tungsten inserts into components suppresses noise and dissipates mechanical vibrations.

Weighting agents

Small tungsten powder volumes incorporated into matrices like polymers, paints, ceramics, cement increase density.

Sporting equipment

Golf clubs, darts, fishing lures and arrows taking advantage of compact heavyweight powder mixtures.

Momentum wheels

Tungsten composite wheels offer excellent rotational inertia within constrained volumes ideal for satellite attitude control.

Elektroden

Tungsten’s high temperature hardness retained at melting point aids electrical discharge machining electrodes and welding tips.

Specificaties

Key parameters defined for high density tungsten powder:

Cijfers

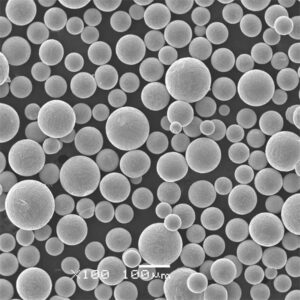

Based on particle size distribution:

| Cijfer | Deeltjesgrootte | Schijnbare dichtheid |

|---|---|---|

| Ultrafijn | 0.2 to 1 μm | ≥ 9 g/cm<sup>3</sup> |

| Submicron | 1 to 5 μm | ≥ 3.2 g/cm<sup>3</sup> |

| Prima | 1 to 10 μm | ≥ 2 g/cm<sup>3</sup> |

| Medium | 10 to 25 μm | ∼7 to 8 g/cm<sup>3</sup> |

| Ruw | 25 to 45 μm | ∼8 to 9 g/cm<sup>3</sup> |

Smaller particles offer higher final density but poorer powder flow and handling. Larger particles provide better green strength.

Normen

- ASTM B777 – Standard Classification of Tungsten Powders and Powder Products

- ISO 4499 – Metallic powders – Determination of oxygen content by reduction methods

- IEC 60804 – Specification for tungsten powders and tungsten metal powders for lamps

Prijzen

Representative pricing of tungsten powder suitable for high density uses:

| Cijfer | Prijs |

|---|---|

| Ultrafijn | $800 to $1200 per kg |

| Submicron | $500 to $900 per kg |

| Prima | $100 to $250 per kg |

| Medium | $50 to $150 per kg |

| Heavy Alloys | $40 to $100 per kg |

Smaller particle sizes, higher purity, special dopants, and lower quantity increase cost. Recycled scrap powder is cheaper.

Voor- en nadelen

Voordelen

- Highest achievable density metal powder

- Near net-shape manufacturability

- Uniform microstructure from powders

- Agglomeration increases apparent density

- Ease of forming complex or hollow shapes

- Precursor for specialty nanomaterials

Nadelen

- Lower hardness than cobalt cemented tungsten carbide

- Limited toughness and ductility

- Challenging machining characteristics

- Relatief duur vergeleken met staalpoeders

- Heavy weight drives shipping costs

- Special handling of fine powders needed

Understanding unique benefits against limitations helps utilize wolfraampoeder met hoge dichtheid optimally.

Leveranciers

Prominent merchants and manufacturers supplying high density tungsten and tungsten alloy powders globally include:

| Bedrijf | Locations |

|---|---|

| Buffelwolfraam | Verenigde Staten |

| Wolfram-bedrijf | Oostenrijk |

| Plansee Groep | Europa |

| Wolfraam uit het Middenwesten | Verenigde Staten |

| Xiamen Wolfraam | China |

| JX Nippon | Japan |

| Toshiba-materialen | Japan |

| GTP Schaefer | Duitsland |

These corporations cater reliable world-class powders to commercial markets.

Veelgestelde vragen

| Vraag | Antwoord |

|---|---|

| What is high density tungsten powder? | Tungsten powder possessing density from 18 to 19.3 g/cm<sup>3</sup> – highest among all metal powders |

| How is high density tungsten powder manufactured? | Reduction of purified tungsten oxide combined with specialized milling for desired particle sizes |

| What is high density tungsten powder used for? | Fabricating counterweights, radiation shielding, ballast, weighting compounds, vibration damping components, etc. |

| What are the different varieties of high density powders? | Pure tungsten, doped tungsten with rare earth oxides, tungsten-nickel-iron alloys, tungsten heavy alloys etc. |

| What are the advantages of high density tungsten powder? | Extreme density in compact volumes unmatched by other powders; net-shape manufacturability into complex parts |

| What are the limitations of tungsten powders while using them? | Relatively lower hardness than tungsten carbide; limited toughness and ductility pose machining challenges |

| How does high density tungsten powder compare against traditional dense materials like lead? | Safer than toxic lead; higher melting point than lead; economically priced against precious metals with similar density |

Samenvatting

With extraordinary density among elemental metals, high purity tungsten powder offers designers unique capabilities for weight-sensitive applications needing compact profiles not feasible earlier. Advances in powder manufacture, pressing, sintering and secondary processing overcome brittleness limitations unlocking wider use. Blending and alloying provides additional tailoring of physical properties across demanding electrical, nuclear, automotive and aerospace domains where high density couples critically with strength, hardness and thermal pedigree.

As sustainable sources back reliable global supply chains, designers now harness density extremes in tungsten powder towards precision engineering functionality across industries where heaviness and compactness together drive value. Leading manufacturers will pursue crossing density thresholds beyond 20 g/cm3 in the coming decade as tungsten assumes greater strategic importance.