aluminiumlegering 7050 poeder is a high-strength aerospace alloy also available in powder form for additive manufacturing and other powder metallurgy applications. With zinc and magnesium as primary alloyants, this 7xxx series alloy demonstrates superior mechanical properties ideal for critical structural components.

Overzicht of aluminium alloy 7050 powder

Al7050 alloy powder offers:

- High strength-to-density ratio

- Lightweighting potential

- Corrosieweerstand

- Dimensional stability

- Fabricability using additive manufacturing

- Recycleerbaarheid

Key properties include high yield strength up to 500 MPa, tensile strength exceeding 570 MPa, and useful fatigue resistance combined with reasonable fracture toughness over 150 MPa-m^1/2^.

These attributes allow designed application across aerospace, automotive, marine and general engineering domains. Al7050 powder can be used to print near-net shape metal components via laser powder bed fusion, binder jetting and directed energy deposition additive technologies.

Types of Aluminium 7050 Powder

Based on production method and characteristics, common Al7050 powder varieties include:

| Type | Beschrijving | Deeltjesgrootte | Morfologie | Schijnbare dichtheid |

|---|---|---|---|---|

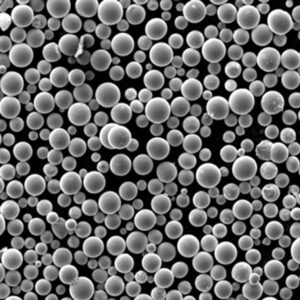

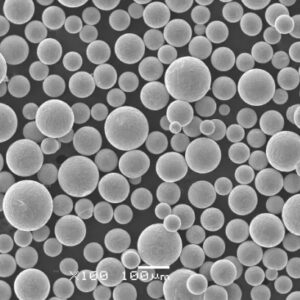

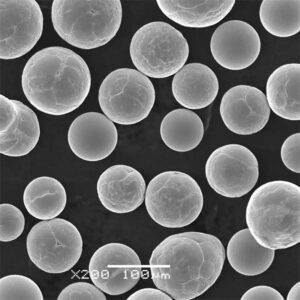

| Gas verneveld | Inert gas atomization provides spherical powder | 15-45 µm | Afgerond | ∼1.6 g/cc |

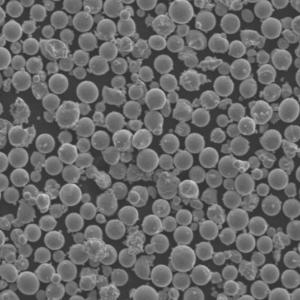

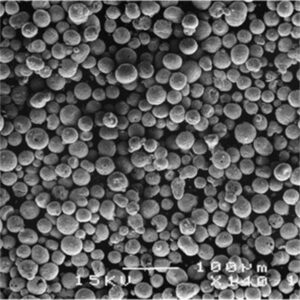

| Water verneveld | Water breaking up of melt forms irregular particles | 15-100 μm | Jagged, porous | ∼1.2 g/cc |

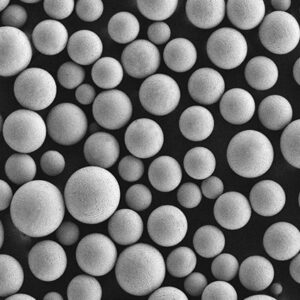

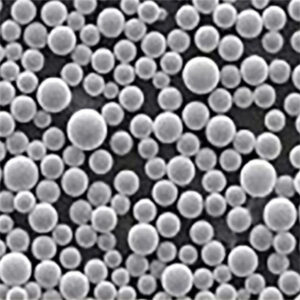

| Plasma verneveld | Smooth, spherical nano-to-micron powder from plasma | 5-45 μm | Very spherical | ∼2 g/cc |

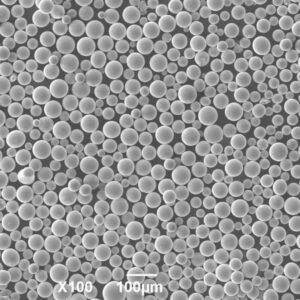

| Mechanical alloyed | High-energy ball milling blendes and refines powder | 15-100 μm | Jagged, composite particles | ∼1.8 g/cc |

Based on final application method, suitable grade is chosen. Smaller sizes below 100 microns allow better powder bed densities and printing resolution.

Samenstelling of aluminium alloy 7050 powder

As an aerospace structural alloy, 7050 composition is:

| Element | Gewicht % | Rol |

|---|---|---|

| Zink | 5.7 – 6.7% | Major alloying element, improves strength through precipitation |

| Magnesium | 1.9 – 2.6% | Strengthening element, forms MgZn2 precipitates |

| Koper | 2.0 – 2.6% | Helps fine-tune mechanical properties |

| Ijzer | ≤0,15% | Impurity level, kept low |

| Silicium | ≤0.12% | Impurity element |

| Chroom | ≤0.04% | Present only as trace impurity |

| Mangaan | ≤0,05% | Kept low as impurity |

| Aluminium | Evenwicht | Basiselement |

intentional additions of silver, lithium or other elements are sometimes used to modify powder characteristics.

aluminiumlegering 7050 poeder Eigenschappen

Key properties of Al7050 alloy powder suitable for additive manufacturing:

Fysieke eigenschappen

| Eigendom | Waarde |

|---|---|

| Dikte | 2.83 g/cm<sup>3</sup> |

| Smeltpunt | ∼635°C |

| Warmtegeleiding | 130 W/mK |

| Specific Heat Capacity | 0.88 J/g-K |

| Elektrische weerstand | ∼4.5 μΩ-cm |

| CTE | 23 μm/m-K |

| Kleur | Dark gray to black |

Low density coupled with strength makes Al7050 suited for aerospace and aviation sectors enabling weight savings.

Mechanische eigenschappen

| Eigendom | Zoals afgedrukt | Heat-treated |

|---|---|---|

| Treksterkte | ≥450 MPa | ≥570 MPa |

| Opbrengststerkte | ≥400 MPa | ≥500 MPa |

| Verlenging | ∼8% | ∼10% |

| Hardheid | ∼150 VPN | ∼195 VPN |

| Vermoeidheid Sterkte | 100 MPa | 230 MPa |

Controlled low-stress heat treatment develops optimal precipitation microstructure enhancing mechanical performance.

Performance Attributes

| Parameter | Waarde | Unit |

|---|---|---|

| Strength-to-weight ratio | Hoog | MPa/(g/cm<sup>3</sup>) |

| Stiffness-to-weight ratio | Hoog | GPa/(g/cm<sup>3</sup>) |

| Corrosieweerstand | Goed | – |

| Lasbaarheid | Eerlijk | – |

| Geleidbaarheid | Uitstekend | %IACS |

| Prestaties bij hoge temperaturen | Goed | – |

These characteristics make Al7050 suitable for commercial and defense aerospace applications.

Productie of aluminium alloy 7050 powder

Key steps in aluminium alloy 7050 powder manufacture:

1. Melting – Primary aluminium ingots are induction melted along with master alloys

2. Atomization – High-pressure gas or plasma atomizes the molten stream into fine droplets

3. Powder cooling – Controlled cooling rates ensure optimal particle solidiication

4. Sieving – Multi-step screening classifies powder into use-specific fractions

5. Blending – Powder lots with slight compositional variations are blended

6. Packaging – Powder is filled into drums or containers under inert atmosphere

Water atomization, mechanical alloying and special chemical methods also produce alloyed Al7050 powder.

Toepassingen of aluminium alloy 7050 powder

Major application areas for Al7050 powder include:

Lucht- en ruimtevaartcomponenten

Al7050 printed parts for structural brackets, wing spars, impellers etc. where weight saving is critical

Automotive assemblies

Lightweight chassis, suspension and transmission elements manufactured via powder bed fusion

Maritieme hardware

Corrosion resistant Al7050 suitable for ocean-going boat components exposed to salt spray

Industrial tooling

Customized jigs, fixtures, grippers and end-effectors 3D printed onsite from Al7050 powder fedstock

Luxury products

High resolution binder jetting used for decorative aluminium objects with fine detailing

Defense components

Load-bearing armour fabricated using latest variable LPF parameters and optimized Al7050 powder

aluminiumlegering 7050 poeder Specificaties

Critical parameters defined for Al7050 powder:

Cijfers

Per MPIF 35 standards based on particle size:

| Cijfer | Deeltjesgrootte |

|---|---|

| Ultrafijn | 1 – 20 μm |

| Very Fine | 15 - 45 μm |

| Prima | 25 – 75 μm |

| Relatively Coarse | 53 – 105 μm |

Ultrafine and very fine Al7050 suitable for laser-based fusion.

Normen

- ASTM B233 – Standard for Aluminum Powder and Flake for Thermal Spraying

- MPIF 35 – Standard for Aluminum and Aluminum Alloy Powders

- ISO 22053 – Determination of particle size of metal powders used for additive manufacturing

Prijzen of aluminium alloy 7050 powder

Representative pricing, 2023:

| Cijfer | Prijs |

|---|---|

| Ultrafijn | $45 – $55 per kg |

| Very Fine | $35 – $50 per kg |

| Prima | $18 – $35 per kg |

| Ruw | $12 – $25 per kg |

Higher sphericity, smaller and narrow distribution powder sizes command premium pricing.

Voor- en nadelen

Voordelen

- Combination of strength and low density

- Heat treatability for tuned properties

- Resilient to fatigue stresses

- Corrosion resistance in multiple mediums

- Recyclable and environmentally sustainable

- Readily processed into end-use shapes

Nadelen

- Lower high temperature capability than steels

- Inferior wear resistance versus harder alloys

- Relatively expensive compared to unalloyed aluminum

- Limited joining and coating options

- Higher CTE than composites, ceramics

Understanding unique capabilities and limitations helps engineers apply Al7050 appropriately.

aluminiumlegering 7050 poeder Leveranciers

Prominent Al7050 powder manufacturers include:

| Bedrijf | Plaats |

|---|---|

| Alpoco | Groot-Brittannië |

| AMC-poeders | Duitsland |

| Metaalpoeders maken | Groot-Brittannië |

| Sandvik Visarend | Groot-Brittannië |

| PyroGenesis | Canada |

| TLS-techniek | Duitsland |

These and secondary LPF machine suppliers provide application-specific Al7050 powder lots to industrial buyers.

Veelgestelde vragen

| Vraag | Antwoord |

|---|---|

| What is aluminium alloy 7050 powder? | Spheroidal gas or water atomized powder of the 7xxx series aerospace alloy with primary alloying additions of zinc and magnesium |

| What is 7050 alloy powder used for? | Additive manufacturing of lightweight structural components for aviation, automotive and marine applications |

| What is the typical composition of Al7050 powder? | ∼6% zinc, ∼2.5% magnesium, ∼2.4% copper balanced by aluminium plus trace elements like Fe, Si, Mn. |

| What are the different varieties of Al7050 powder? | Gas atomized, water atomized, plasma atomized and mechanically alloyed powder |

| What are the properties of Al7050 alloy powder? | Density – 2.83 g/cm<sup>3</sup>; tensile strength – over 500 MPa; hardness – 150 to 200 VPN; excellent strength-to-weight ratio; moderate corrosion resistance |

| What is the typical particle size of Al7050 powder for additive manufacturing? | 15 to 45 microns classified into Very Fine grade size |

| Does Al7050 powder require deoxidation or spheroidization before use? | Desirable to have lower than 50 to 100 ppm oxygen content; sphericity over 0.9 preferred |

| Is Al7050 hazardous during handling and storage? | No major hazards, but inhalation of fine powder can cause respiratory irritation |

Samenvatting

With a potent blend of high strength, respectable fracture toughness and moderate corrosion resistance, aluminum 7050 alloy demonstrates attractive properties from among nonferrous powder options for additive manufacturing. Careful attention to powder quality and recyclability promises exceptional in-service structural performance once components are processed via latest generation large powder bed systems.

As aluminum alloys gain wider acceptance across aviation, rocketry and premium automotive sectors, Al7050 powder will spearhead manufacturability of complex lightweight shapes and lattices hitherto unviable, backing new levels of functionality.