3D printen, ook bekend als additive manufacturing (AM), maakt gebruik van gespecialiseerde poeders om driedimensionale onderdelen te construeren in opeenvolgende lagen. Deze gids is een diepgaand naslagwerk over poeders voor 3D printen - met informatie over types, eigenschappen, specificaties, productiemethoden, belangrijkste leveranciers en prijzen, toepassingen in verschillende sectoren, vergelijkingen met alternatieven, veelgestelde vragen en nog veel meer.

Overzicht van Poeders voor 3D afdrukken

3D printing powders are raw material feedstocks enabling additive part fabrication across plastic, metal and ceramic platforms. Key traits:

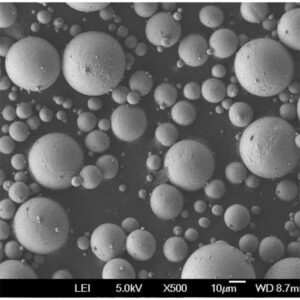

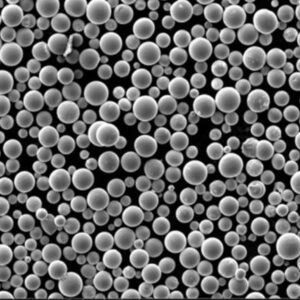

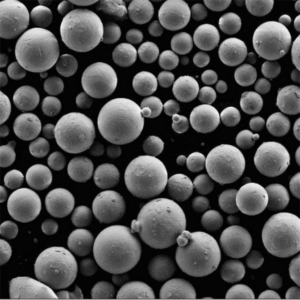

- State: Ultrafine particulate powders

- Size range: Typically 10-150 microns

- Morphology: Most often spherical particle shape

- Composition: Polymer, metal alloy, ceramic, sandstone blends

- Key properties: Engineered particle size distribution, flowability, pack density and microstructure

By leveraging tight control of powder physical properties and interactions with thermal/kinetic printing processes, 3D printing powders facilitate intricate part geometries and material compositional gradients not achievable otherwise.

Soorten 3D Printing poeders

| Categorie | Materialen | Afdrukmethode |

|---|---|---|

| Kunststoffen | Nylons, ABS, TPU, PEKK, PEEK… | Selectief lasersinteren (SLS) |

| Metalen | Stainless, tool steels, titanium & alloys, superalloys… | Direct metaallasersinteren (DMLS) |

| Keramiek | Alumina, zirconia, silicon carbide | Binder jetting, fused deposition modeling |

| Composieten | Metal/plastic blends, sandstone mixes | Multi jet fusion (MJF), bound metal deposition |

| Bio-compatible | PEEK, PLGA, TCP… | Selectief lasersmelten (SLM) |

Tafel 1: Major categories, materials and associated printing platforms for commercial 3D printing powders

Polymer, metal, ceramic and composite powders support production of end-use parts across aerospace, automotive, medical, dental and industrial markets.

Productiemethoden

Key techniques to produce printing powders include:

Kunststoffen

- Polymerization of monomers

- Phase inversion

- Cryogenic grinding of bulk plastics

Metalen

- Gasverneveling

- Plasma-verneveling

- Elektrode inductie smelten

Keramiek

- Sol-gel routes

- Emulsification methods

- Spray drying processes

Tailoring manufacturing steps allows tuning powder particle size distributions, morphology, microstructure, chemistry and resulting performance to match 3D printing process and application requirements.

Eigenschappen van Poeders voor 3D afdrukken

| Eigendom | Role in Printing Process |

|---|---|

| Deeltjesgrootteverdeling | Impacts packing density, spreadability, flow and adhesion between layers |

| Deeltjesvorm | Spherical preferred for smooth flow versus jagged particles |

| Particle hardness | Resists deformation during roller/blade spreading steps |

| Bulkdichtheid | Enables sufficient powder layer thickness for build stage |

| Scheikunde | Determines mechanical performance, aesthetics of final part |

| Vochtgehalte | Influences powder flow and adhesion |

Tafel 2: Key powder physical attributes vital to 3D printing success

Inadequate control of these interrelated powder characteristics results in poor flow, spreading, lamination irregularities, part defects and mechanical property reduction.

3D-Printpoeder Specificaties

Industry standards exist for most polymer, metal and ceramic 3D printing powders:

Deeltjesgrootteverdeling

| Cijfer | Specificatie | Example Materials |

|---|---|---|

| Ultrafijn | D10: 10-25μm D50: 20-45μm D90: 40-75μm | PEEK, PEKK High temp polymers |

| Prima | D10: 40-75μm D50: 60-90μm D90: 90-150μm | Nylon, ABS metals |

| Medium | D10: 75-100μm D50: 100-150μ D90: 130-200μm | Sandstone mixes, ceramics |

Repeatability Standards

| Metrisch | Tolerance |

|---|---|

| Particle size distribution batch-to-batch | ± 5% |

| Particle shape batch-to-batch | ± 5% circularity |

| Bulk density batch-to-batch | ± 2% |

Table 3A: Particle size distribution profiles for polymer, metal & ceramic 3D printing powders

| Eigendom | Test methode | Threshold |

|---|---|---|

| Debiet van de hal | ASTM B213 | <40 s for 50 g to flow |

| Schijnbare dichtheid | ASTM B212 | Min 60% theoretical density |

| Tik op dichtheid | ASTM B527 | Min 65% theoretical density |

Table 3B: Key quality checks for 3D printing powder flow and density

Meeting or exceeding published specs ensures batches perform consistently.

3D drukpoeder leveranciers

Many providers offer 3D printing powders for polymers, metals and ceramics:

Polymeerpoeder

| Bedrijf | Materialen | Price/kg |

|---|---|---|

| Evonik | Nylon 12, PEEK, TPU, PEKK | $50-260 polymer dependent |

| BASF | Ultrasint PA6, PA11, PA12 grades | $75-215 |

| Stratasys | Thermoplastic composites | $140-350 |

| Polymaker | PolySmooth, PolyLite, PolyFlex | $35-90 |

Metaalpoeders

| Leverancier | Alloy Types | Indicatieve prijzen |

|---|---|---|

| Timmerman additief | Stainless, tool steel, cobalt chrome, superalloys | $55-215 alloy specific |

| Praxair | Titanium Ti64, Inconel 718, 316L stainless | $35-185 |

| Sandvik Visarend | Maraging steel, stainless grades, Ni superalloys | $75-305 alloy dependent |

| LPW-technologie | Aluminum AlSi10Mg, titanium Ti64, superalloys | $45-195 |

Ceramic & Composite Powders

| Brand | Materialen | Price Ranges |

|---|---|---|

| 3DCeram | Alumina, zirconia, silica | $35-125 ceramic specific |

| Adaptive3D | Thermosetting & thermoplastic composites/blends | $90-350 |

| Tritone | PEEK, PEKK, PPSU + ceramic filled | $125-475 formula dependent |

Tabel 4: Specialist manufacturers offer range of 3D printing powders

Prices vary reflecting proprietary compositions and performance capabilities – contact suppliers directly with volume requirements for exact quotes. Some providers offer samples for testing.

Toepassingen van Poeders voor 3D afdrukken

Printing powders uniquely facilitate complex, customized part geometries across industries:

| Industrie | Example Components | Voordelen |

|---|---|---|

| Lucht- en ruimtevaart | Turbine blades, rocket nozzles, UAV chassis | Weight reduction, performance gains |

| Medisch | Patient-matched implants, prosthetics | Personalized sizing, bio-compatibility |

| Automobiel | Heat exchangers, lightweight chassis elements | Parts consolidation, efficiency |

| Industrieel | Custom production tooling, jigs | Shortened development timelines |

Tabel 5: Major use case sectors taking advantage of 3D printing powder capabilities

The ability to rapidly iterate designs and print short runs economically enables end-use part innovation.

Pros and Cons of Powder-Based 3D Printing

Advantages Over Subtractive Techniques

- Facilitates intricate, lightweight geometries for efficiency gains

- Optimizes material microstructures for enhanced part performance

- Achieves customized components matched to applications

- Reduces development/production time and capital costs

Downsides To Consider

- Limited production scale and throughput in some processes

- Stringent specifications required for powder feedstock

- Post-processing often necessary for final part |

- Part costs currently higher than mass manufacturing |

Fine tuning powder chemistry and printing parameters targets more efficient production. Fields leveraging customization and performance continue aggressive adoption.

Veelgestelde vragen

Q: What particle size range works best for metal 3D printing powders?

A: 10-45 microns facilitates good packing and spreading while avoiding challenges with ultrafine powders around powder handling. Most alloys perform well 30±15μm distribution.

Q: Which polymer powder 3D printing process offers the best mechanical performance?

A: Selective laser sintering (SLS) allows excellent fusion and fine feature production – creating high performing plastic parts rivaling or exceeding injection molding processes.

Q: How long can unused 3D printing powder last in storage?

A: Kept sealed with desiccant from moisture in a cool, dry environment – powders maintain flow characteristics at least 12 months. Even opened powders last 6+ months before notable degradation.

Q: Does the quality of starting powder significantly influence printed part properties?

A: Yes, powder chemistry purity plus adequate control of powder characteristics strongly determine final part mechanical properties, aesthetics, dimensional accuracy and performance reliability.