Overzicht van 3D printen van aluminiumlegeringen

3d printing aluminum alloys offer several beneficial characteristics like high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance that make them suitable materials for 3D printing applications across automotive, aerospace, consumer goods, and other industries.

Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the primary 3D printing processes used for aluminum alloy powders. The powders particles are fused together layer-by-layer using a high power laser to construct complex and customizable component geometries.

Types van 3D printen van aluminiumlegeringen

| Alloy Series | Algemene cijfers | Kenmerken |

|---|---|---|

| 2xxx Series | 2024, 2219, 2519 | Heat treatable, high strength |

| 5xxx Series | 5005, 5052, 5083 | Moderate strength, weldable |

| 6xxx Series | 6060, 6066, 6061 | Heat treatable, machinability |

| 7xxx Series | 7050, 7068, 7075 | Very high strength, low corrosion resistance |

Samenstelling van 3D printen van aluminiumlegeringen

Aluminum alloys contain over 97% aluminum by weight along with alloying elements like magnesium, silicon, manganese, and copper added to enhance certain properties like:

- Magnesium – Increases strength, formability

- Silicon – Improves fluidity for casting applications

- Manganese – Added to control grain structure

- Copper – Increases strength and machinability

- Zinc – Improves strength through precipitation hardening

- Chromium – Controls grain size for higher toughness

Mechanische eigenschappen

3D printed aluminum components demonstrate high mechanical strength similar to cast or wrought alloys. Some typical values are:

- Treksterkte – 340 to 565 MPa

- Opbrengststerkte – 170 to 505 MPa

- Rek bij breuk – 3% to 8%

- Hardheid – 75 to 110 HRB

- Modulus of elasticity around 70 GPa

Characteristics of 3D Printable Aluminum

| Attribuut | Details |

|---|---|

| Oppervlakteafwerking | Powder adhesion can leave semi-rough, stepped surface profile |

| Nauwkeurigheid | Generally high dimensional accuracy up to ±0.1% is possible |

| Anisotropie | Directionally weaker mechanical properties observed |

| Porositeit | <1% porosity achieved under optimized SLM parameters |

| Alloy Flexibility | Many 2xxx, 5xxx, 6xxx, and 7xxx grades printable |

Toepassingen van 3D printen van aluminiumlegeringen

| Industrie | typische applicaties |

|---|---|

| Lucht- en ruimtevaart | Aircraft ductwork, heat exchangers, structural brackets |

| Automobiel | Custom brackets, supports, heat sinks, tooling |

| Architectuur | Lightweight panels, decorative lattices, small sculptures |

| Medisch | Firmware like surgical instruments, implants |

| Elektronica | Heat dissipation devices like heat sinks |

| Verdediging | Low volume parts with reduced lead times |

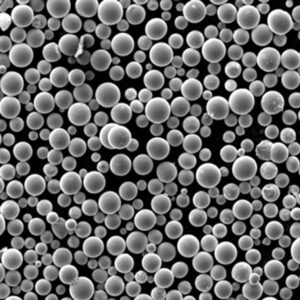

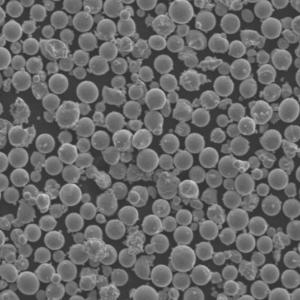

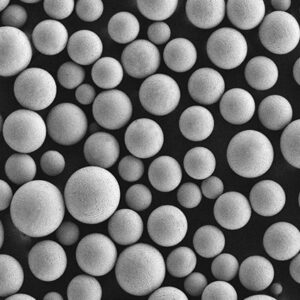

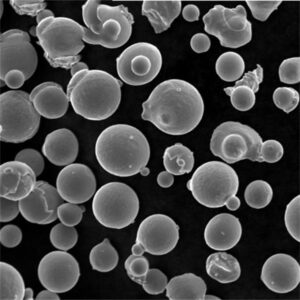

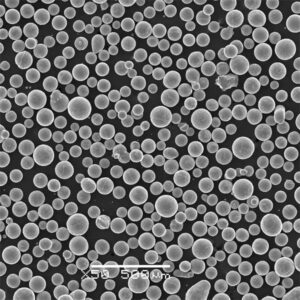

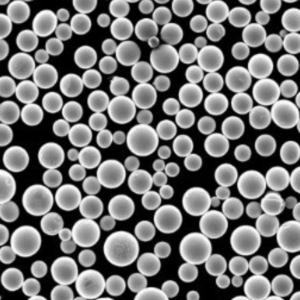

Aluminum Powder Specifications for Additive Manufacturing

| Parameter | Type/Range |

|---|---|

| Materialen | AlSi10Mg, AlSi7Mg0.6, AlSi12, AlSi9Cu3 |

| Deeltjesgrootte | 25 to 65 microns |

| Deeltjesvorm | Mostly spherical, some satellites allowed |

| Schijnbare dichtheid | Around 2.67 g/cc |

| Stroomsnelheid | <30 s/50 g per ASTM B964 |

| Resterende zuurstof | <0.4% for high tensile strength |

Toonaangevende leveranciers van 3D printen van aluminiumlegeringen

Popular aluminum alloy powder producers for AM include:

- AP&C – Specializes in atomization of reactive materials like aluminum

- Carpenter Additive – Broad range of stainless steel and aluminum grades

- EOS – Supplies pre-alloyed aluminum powders for EOS printing systems

- Sandvik Osprey – Spherical gas-atomized aluminum powders

- SLM Solutions – Optimization for SLM printers with high quality aluminum

Cost Considerations

| Aluminum Grade | Average Powder Price |

|---|---|

| AlSi10Mg | $100-150 per kg |

| AlSi7Mg | $70-100 per kg |

| AlSi12 | $90-140 per kg |

Virgin aluminum powders carry a premium of 20-50% over recycled powders. Prices also depend on quantity purchased, particle characteristics, supplier, and prevailing metal prices.

Pros and Cons of 3D Printed Aluminum

| Voordelen | Nadelen |

|---|---|

| Weight reduction versus steel parts | Hoge reflectiviteit vereist een hoger laservermogen |

| Rapid prototyping, customization | Post-processing often needed to relieve stresses |

| Consolideert samenstellingen in één onderdeel | Reactive aluminum requires inert atmospheres |

| Improved thermal management | Maximum part size limited by equipment used |

| Compatible with plating, polishing | Alloys have lower max service temp than steels |

FAQ

Q: Which aluminum alloy is best suited for additive manufacturing?

A: AlSi10Mg is the most widely adopted aluminum alloy offering a good combination of fluidity, strength, hardness and corrosion resistance combined with compatibility across various printers.

Q: Does build orientation affect properties of 3D printed aluminum components?

A: Yes, building vertically can exhibit 20-30% lower tensile and yield strengths versus horizontally built parts due to layer-by-layer construction. Mechanical performance also varies depending on loading parallel or perpendicular to layers.

Q: What solution heat treatments can enhance aluminum properties?

A: T6 heat treatment (solubilize then artificially age harden) of some additively manufactured alloys like AlSi10Mg can significantly increase tensile strength, hardness and ductility compared to as-built state.

Q: How are surface finishes improved for additively made aluminum parts?

A: Various finishing procedures like sand blasting, bead blasting, laser polishing, CNC machining, grinding or linishing can help smooth out the stepped contours typically observed on as-built aluminum surfaces from powder-based printing.

Q: Does aluminum powder reuse affect 3D printed part properties?

A: Recycling aluminum build powder upto 10-20 times typically does not impact mechanical performance. But beyond around 25 reuse cycles, declining powder flowability, lower density, and higher oxygen/nitride impurities can start deteriorating material quality and strengths.