3D printing technology relies on powdered material to build objects layer-by-layer. Selecting the right powder is critical for part quality, mechanical properties, accuracy, detail resolution, and surface finish. This article provides an overview of different types of powders used in major 3D printing processes, their composition, key properties, applications, and leading global suppliers.

Overzicht van 3d printer poeder leveranciers

3D printing, also known as additive manufacturing, utilizes powdered polymers, metals, ceramics, or composites as raw material input stock. Based on the technology and materials used, powders can be engineered with specific particle size distributions, morphology, flow characteristics, melting points, and other physical and chemical attributes tailored to the printing process.

Types of 3D Printer Powders

Several key technologies rely on powder bed fusion to selectively melt and solidify material layer-by-layer to fabricate 3D objects. Popular processes and associated powders include:

| Proces | Materialen |

|---|---|

| Selectief lasersinteren (SLS) | Thermoplastic powders like nylon, TPU, PEEK |

| Direct metaallasersinteren (DMLS) | Metal powders like aluminum, titanium, steel alloys |

| Elektronenbundelsmelten (EBM) | Titanium alloys, cobalt chrome, stainless steel |

| Binder jetting | Stainless steel, tool steel, tungsten carbide |

| Stereolithografie (SLA) | Ceramic suspended photopolymer resins |

Composition of Polymer Powders for SLS

Selective laser sintering relies on fine polymer powders with controlled particle size distribution and morphology. Common materials include:

| Polymer | Belangrijkste eigenschappen | Toepassingen |

|---|---|---|

| Nylon 12 | Toughness, flexibility | Functional prototypes, end-use parts |

| Nylon 11 | High strength, heat resistance, bio-compatibility | Aerospace, automotive, medical |

| TPU | Elasticity, abrasion resistance | Flexible parts, sporting goods |

| PEEK | Extreme temperature/chemical resistance | Aerospace, oil/gas, medical |

Nylon 12 is the most widely used polymer powder for laser sintering. The composition includes base nylon polymer, flow agents, and other additives:

Nylon 12 Powder Composition

| Onderdeel | Functie |

|---|---|

| Base polymer | Provides mechanical properties, melting behavior |

| Flow agents | Improve powder flow and reduce agglomeration |

| Anti-aging additives | Enhance thermal stability and prevent material degradation over time |

Types of Metal Powders for AM Processes

Common metal powders used in powder bed fusion and binder jetting include:

| Materiaal | Alloys/Grades | Eigenschappen | Key Applications |

|---|---|---|---|

| Aluminium | AlSi10Mg, AlSi7Mg | Lightweight, corrosion resistant | Lucht- en ruimtevaart, automobiel |

| Titanium | Ti-6Al-4V, Ti 6242 | Hoge sterkte-gewichtsverhouding | Lucht- en ruimtevaart, medische implantaten |

| Roestvrij staal | 316L, 17-4PH, 420 | Corrosion/heat resistance | Pompen, kleppen, gereedschap |

| Gereedschapsstaal | H13, P20, D2 | Hardheid, slijtvastheid | Spuitgietmatrijzen, matrijzen |

| Kobalt Chroom | Co28Cr6Mo | Biocompatibility, fatigue/corrosion resistance | Dental, medical |

| Inconel | IN625, IN718 | Sterkte bij hoge temperaturen | Turbinebladen, raketmondstukken |

Titanium alloys like Ti-6Al-4V are extensively used to fabricate strong, lightweight structural components across aerospace, automotive, and medical sectors via DMLS and EBM.

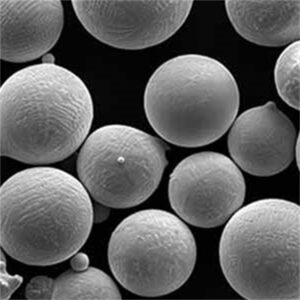

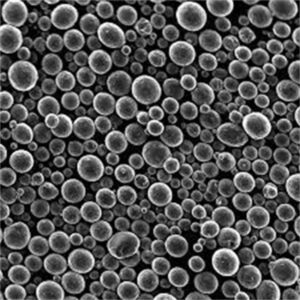

Metal Powder Composition and Production

Most commercial metal powders are produced via gas or water atomization process. The composition includes a base alloying element like titanium or aluminum and other alloying ingredients:

Ti-6Al-4V Powder Composition

| Element | Gewicht % | Doel |

|---|---|---|

| Titaan (Ti) | Evenwicht | Principal element |

| Aluminium (Al) | 5.5-6.75% | Versterking |

| Vanadium (V) | 3.5-4.5% | Verfijning van het graan |

| Ijzer (Fe) | < 0.3% | Impurity |

Other common production methods for metal AM powders include plasma atomization, electrolysis, and chemical reduction. These influence powder characteristics like particle shape, size distribution, flowability, apparent density, and microstructure.

Ceramic & Composite Powders

Ceramics and composites can also be processed via powder bed technologies to create high-performance components:

| Materiaal | Eigenschappen | Toepassingen |

|---|---|---|

| Aluminiumoxide | High hardness, temperature/corrosion resistance | Cutting tools, wear parts |

| Siliciumcarbide | Extreme hardness, thermal shock resistance | Metal cutting, abrasives |

| PEEK polymer | Thermo-mechanical performance | Aerospace composites |

| Continuous fiber composites | Hoge sterkte-gewichtsverhouding | Structural components |

Photo-curable ceramic resin powders containing silicone dioxide nanoparticles suspended in photopolymer are commonly used in high-precision stereolithography printers.

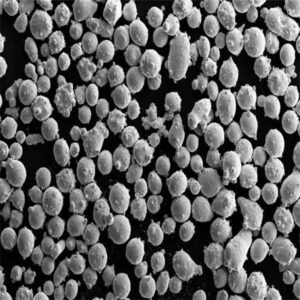

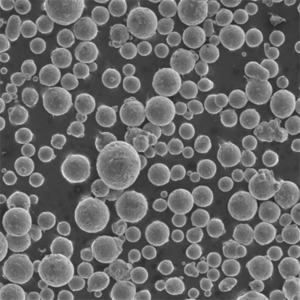

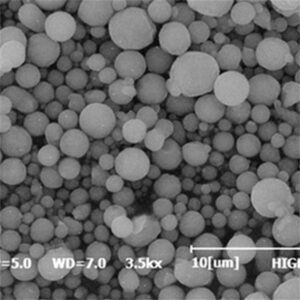

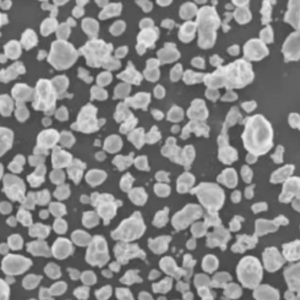

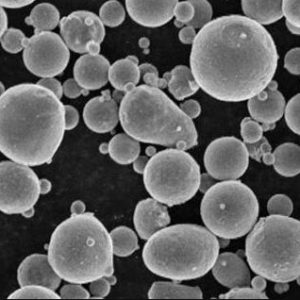

Powder Characteristics and Specifications

3D printer powders must meet strict specifications in terms of particle size distribution, morphology, flow rate, density, and microstructure. Typical values are shown below:

Polymer Powder Specifications

| Parameter | Typische waarde |

|---|---|

| Deeltjesgrootte | 15-150 µm |

| Deeltjesvorm | Bolvormig |

| Schijnbare dichtheid | 0.35-0.55 g/cm<sup>3</sup> |

| Smeltpunt | 172-185°C (nylon 12) |

Metaalpoederspecificaties

| Parameter | Typische waarde |

|---|---|

| Deeltjesgrootte | 15-45 µm |

| Schijnbare dichtheid | 2.5-4.5 g/cm<sup>3</sup> |

| Stroomsnelheid | 25-35 s/50g |

| Oxide-gehalte | < 0.4 wt.% |

| Microstructuur | Fully dense spherical |

Manufacturers provide powder material data sheets specifying physical properties, chemical composition test reports, particle size distribution analysis, flow rate measurements, and scanning electron microscopy images.

Applications of 3D Printing Powders

Polymer and metal powders enable production of end-use components across diverse industries. Some examples include:

Polymeer onderdelen

- Functional prototypes

- Automotive ducting, housings

- Consumer products, sporting goods

- Aerospace interior components

Metal Parts

- Aircraft engine/structural parts

- Turbineschoepen, waaiers

- Biomedical implants, devices

- Injection molds, cutting tools

3D printing powders facilitate complex geometries with enhanced mechanical properties unattainable via traditional casting or machining processes.

Powder Suppliers

Leading global suppliers of powders tailored for major 3D printing technologies include:

Polymeerpoeder

| Bedrijf | Materialen |

|---|---|

| BASF | Ultrasint PA6, PA11, PA12, TPU |

| Henkel | Loctite PA12, PP, TPE |

| EOS | PA2200, PA3200GF |

| Evonik | Vestosint polymers |

Metaalpoeders

| Bedrijf | Materialen |

|---|---|

| AP&C | Titanium-, nikkel-, kobaltlegeringen |

| Sandvik Visarend | Roestvrij staal, gereedschapsstaal, superlegeringen |

| Praxair | Titanium, aluminum, cobalt chrome |

| GE-additief | Stainless steels, CoCr, Inconel |

These companies offer a wide range material grades tailored for SLS, DMLS, EBM, binder jetting with specialized particle size distributions, shapes, purity levels, and alloy chemistries.

Powder Cost Analysis

Material cost is a significant factor in adopting metal AM. Powder pricing depends on composition, production method, quality, and order volume:

| Poeder | Prijsbereik |

|---|---|

| Nylon 12 | $60-100/kg |

| Aluminium AlSi10Mg | $50-150/kg |

| Titaan Ti-6Al-4V | $200-500/kg |

| Nickel IN625 | $100-250/kg |

| Kobalt Chroom | $150-600/kg |

Polymer powders can be 40-90% cheaper compared to exotic aerospace alloys. Recycling used powder via sieving and blending with fresh stocks helps lower material costs.

Pros and Cons of Powder-Based AM

| Voordelen | Beperkingen |

|---|---|

| Complex geometries unattainable by other processes | Generally slower build speeds than traditional methods |

| Consolidated assemblies, reduced part count | Powder removal/cleanup post-processing |

| Customized alloys, composite blends | Anisotrope materiaaleigenschappen |

| Reduced machining compared to subtractive methods | Porosity issues in some laser/e-beam processes |

Samenvatting

In summary, powder bed fusion and binder jetting rely on specially engineered plastic, metal, ceramic, or composite powders with tailored size, shape, composition, and microstructure. Leading polymer options include nylon 12, PEEK, and TPU while common metals encompass aluminum, titanium, and nickel-based alloys. Global suppliers offer wide material selection validated for major AM systems. Choosing application-specific powders matching mechanical requirements and properties is critical for part performance.

Veelgestelde vragen

What are the main types of 3D printing powders?

The four major categories are plastics like nylon 12 and PEEK, metals including aluminum, titanium, and tool steel alloys, ceramics such as alumina or silicon carbide, and polymer/fiber composites.

What powder size is ideal for AM processes?

A typical range is 15-100 microns for metals and 15-150 microns for polymers. Size distribution influences density, flowability, surface roughness, accuracy, and speed.

What production methods are used to manufacture metal powders?

Common techniques include inert gas atomization using argon or nitrogen and water atomization. Some niche alloys rely on plasma atomization, electrolysis or chemical processes.

How do you evaluate fitness of powders for AM?

Key parameters are particle size distribution, flow rate, apparent density, morphology and microstructure. Material certification reports confirm chemical composition, gas/oxide content, and trace impurities.

What post-processing is needed on 3D printed powder parts?

Depending on the material and process, common steps involve support removal, media blasting, annealing, HIP and machining to achieve dimensional accuracy and desired finishes.

What are typical bulk pricing tiers for metal AM powders?

1-5 kg samples cost $100-300/kg. Typical volume orders of 10-100 kg range from $60-250/kg. High-volume >500 kg orders can reach $30-150/kg for common aerospace/tooling alloys.

How does recycled powder impact part quality and mechanical performance?

Repeated recycling beyond 2-3 builds can result in changed size distribution, contamination, buildup of satellites, powder degradation issues causing lower density and poorer mechanicals. Fresh powder blending helps overcome this.

What improvements are expected in future metal powders?

Key focus areas are custom alloys, better powder spreadability and packing density for faster builds, lower porosity and higher density leading to enhanced material properties and surface finishes.